- Industrial Plants, Machinery and Equipment

- Textile

- Maritime

- Food Processing and Distribution

- Leather

- Commercial Vehicles and Fleet Management

- Domestic Appliances and White Goods

- Rubber, Resin and other Natural Polymers

- Software, Apps and Digital Platforms

- Call Center and BPO Services

- Photography and Audio Visual Content

- Aerospace, Satellite Components and Services

- Lighting and Other Home Appliances

- Chemicals, Dyes, Solvents and Petrochemicals

- Healthcare and Diagnostics

- Automobile and Automobile Accessories

- Furniture and Furnishing

- Manufacturing

- Metalworking and Fabrication

- Printing

- Consumer Electronics and Accessories

- Seeds, Fertiliser, Pesticides and Agro-input chemicals

- Handloom, Handicrafts and Carpets

- Fuel and Alternative Fuels

- Plantation, Nursery and Gardening

- Distribution, Conditioning Systems and Plumbing Solutions

- Glass, Glassware, Glass furnaces and other equipment

- Kitchenware and Kitchen Accessories

- Manufacturing Components and Supplies

- IT Services and Telecommunication

- Plastic and Synthetic Polymers

- Mechanical Components and Spare Parts

- Animal Husbandry, Dairy, Fishing and Animal Feed

- Electrical and Electronics Equipment and Components

- Pharmaceuticals

What do you want to Enquire about?

About Us

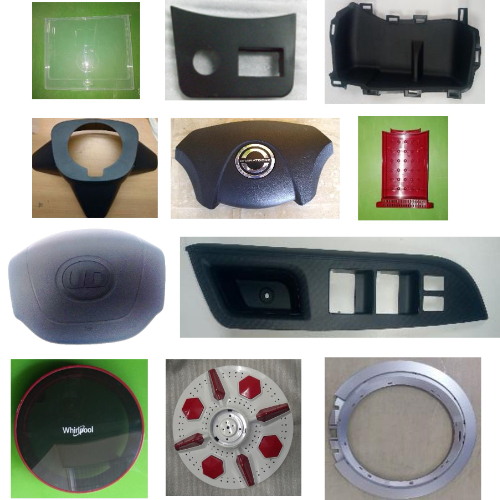

ACT Plast Paints is uniquely positioned in polymer industry with wide range of sophisticated processes and secondary operations to provide one stop solution for automotive and other OEM users of plastics assemblies. Our processes ensure world class quality and meets specifications of global automotive gaints. Inline secondary operations and assembly process ensure minimal lead time and meets day to day supply needs.

View more

Our Leadership Team

Mr. Sivakumar R

Business Head

Mr. Jayepragash L

Business Head

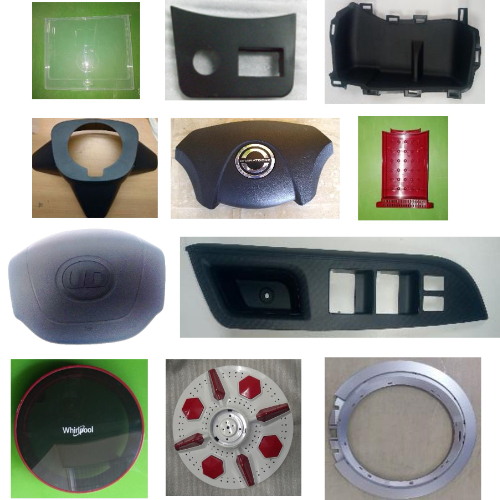

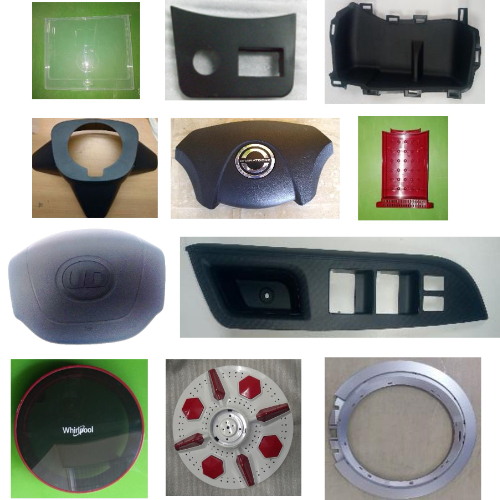

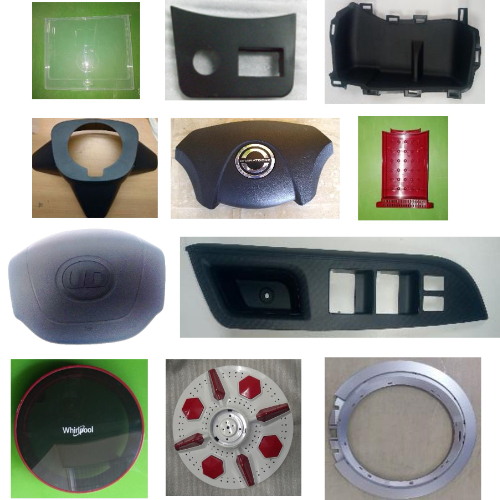

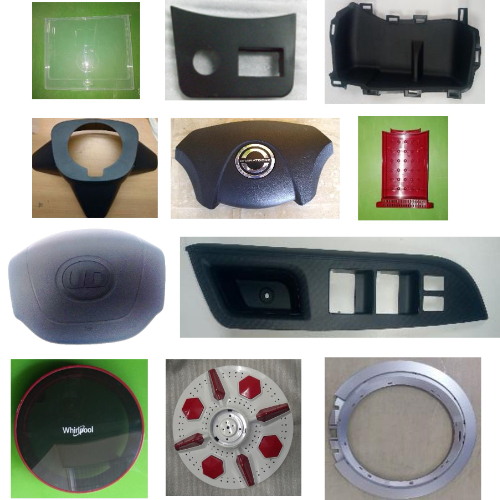

Products & Services

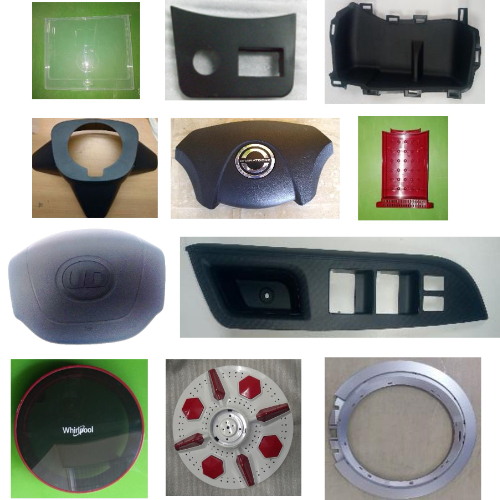

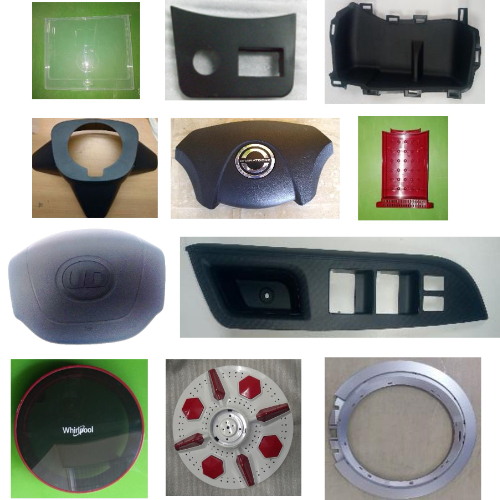

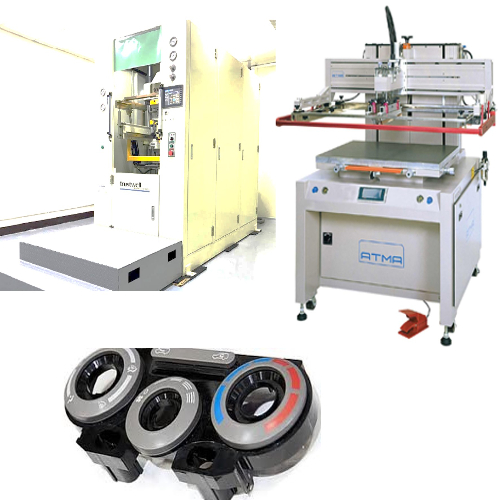

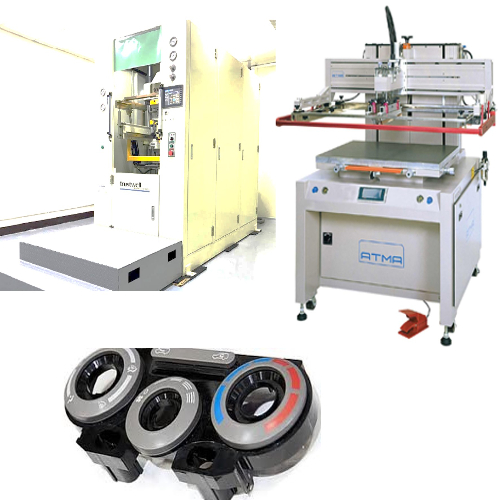

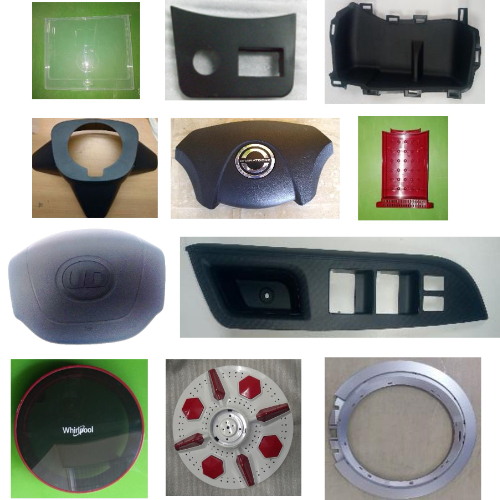

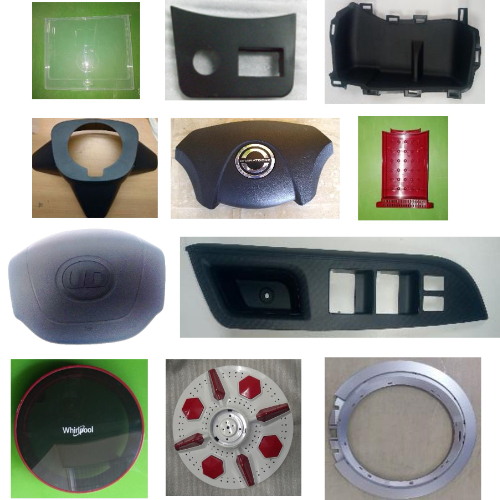

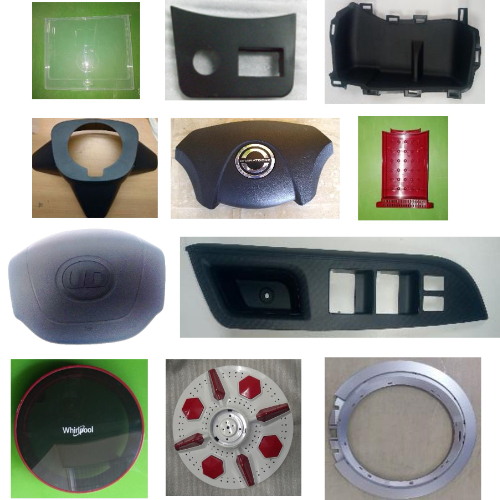

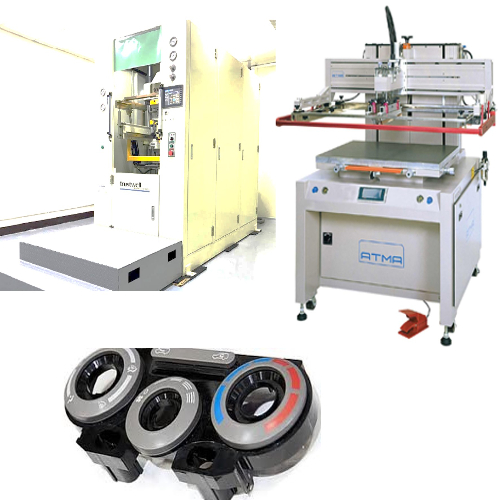

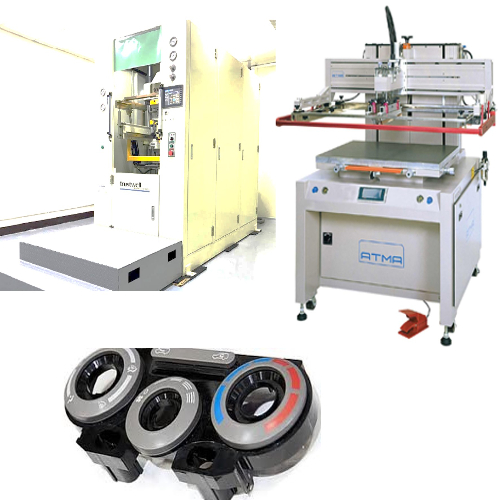

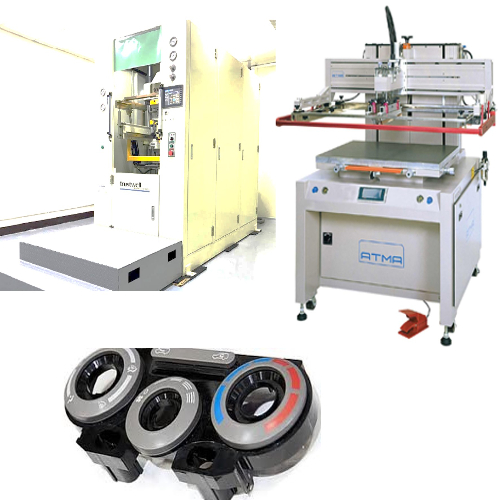

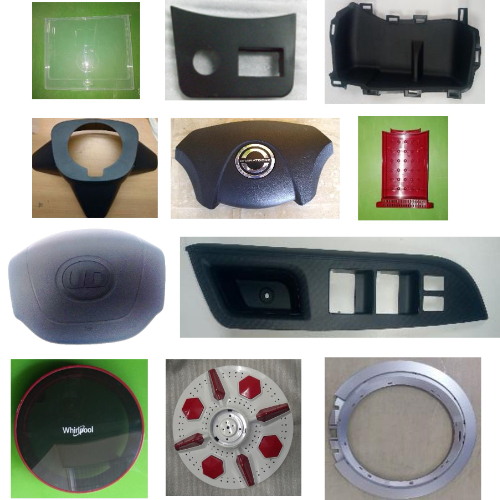

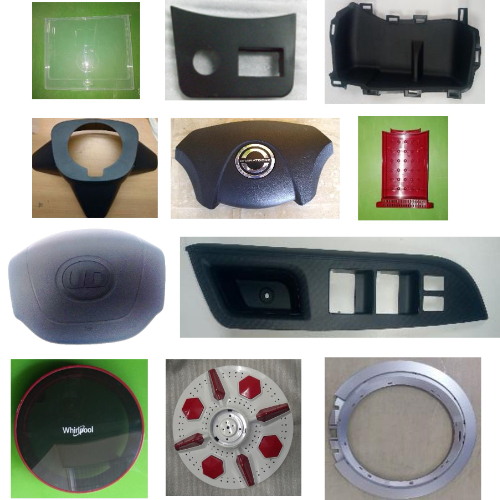

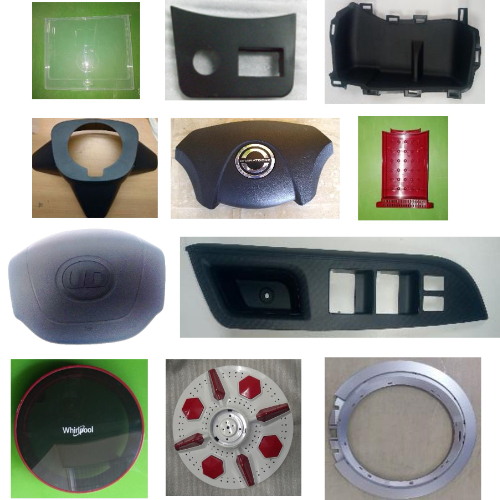

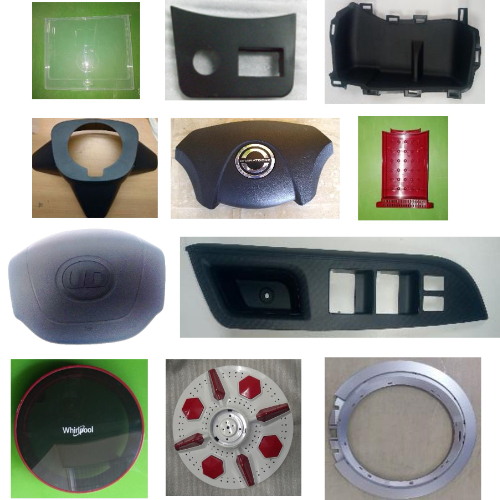

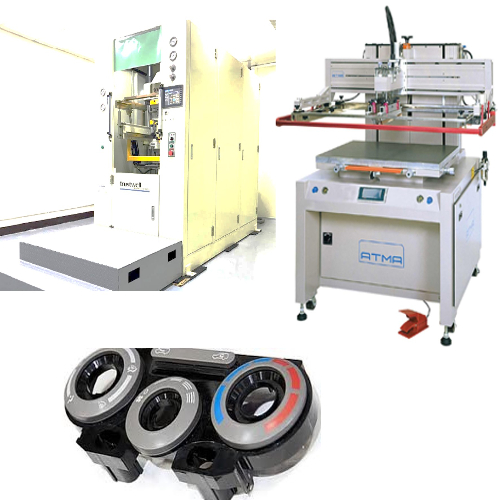

Plastic Injection Moulding

Product Detail

Plastic Injection Moulding

ACT offers high-quality custom plastic injection molding . Whether you need to create a fully functional prototype or large volume production, we make it happen. Integrating 15+ years of manufacturing knowledge with current best practices and technology, we offer a variety of injection molding services and value-added processes to meet all of your needs ranging from single components to full custom manufacturing.

We built our facilities seamlessly integrating a variety of our customers’ custom plastic molding needs. From full engineering to product development support to efficient manufacturing, we offer our customers significant cost savings and additional benefits over our competitors. These include lower costs, decreased setup times, high quality and unmatched precision.

We have 40 Fully Automatic Injection Molding machines with mixed technology . They are Hydraulic and fully electrical machines with capacity ranging from 50Ton to 1300Ton. All these machines are equipped with high end axillaries like Pick and place robots, auto material feeding system, Mold temperature controllers, chillers, sequential gate controllers etc. Product weight ranges from 1 grams to 4500 grams.

+ Show more

- Show less

Painting products

Product Detail

Painting products

We specialize in applying paint over plastic substrates, and our plant is equipped to handle mass production jobs as well as smaller production runs. Our facility houses a fully automated Class A paint line outfitted with the newest technology air filtering systems, proportional mixing stations that assure highest degree of ratio accuracy and intelligent painting robots that operate repeatedly and productively. We also run a manual coating line and have eight manual 3 coat painting lines. Along with conventional curing systems, we also have inline fast-cure infrared ovens that save energy and time.

The types of polymers we commonly paint include ABS, polycarbonate, polypropylene, and other plastics. We offer an extensive selection of 1K and 2K coating systems with a range of performance and protective properties. We also offer custom masking for duel colours in same part. By designing custom paint masks that fit your product perfectly, we produce precise paint edges and clean trim lines with no overspray. Our processes are continuously monitored to ensure accurate and repeatable results, even over the longest production runs. We have a significant presence in the automotive industry and have strong capabilities for painting both interior and exterior components. Our capabilities include the part size ranging from 5 mm to 1800 in length and 1000 mm in width.

+ Show more

- Show less

Pad Printing

Product Detail

Pad Printing

Pad printing is an option that is useful to print on curved and irregular surfaces. Pad printer uses a soft rubber pad to transfer ink from a custom metal plate with the image or logo being printed to a curved, irregular or hard to reach item.

As every project we execute at ACT is a custom project, we specialize in industrial pad printing to serve our customers’ needs. We have the ability to print on variety of materials and handle large volume products. Our ability to create metal plates in-house allows us to produce high-quality image transfers at a lower cost. We have 6 pad printing lines with printing capability of maximum 75mm diameter.

+ Show more

- Show less

Laser Etching

Product Detail

Laser Etching

Laser etching machines are used for high detailed back-lighting purposes and durability. Our engineers have experience etching variable layer thicknesses, coating types and colours to create consistent and accurate durable legends and back-lighting for use on all automotive audio, climate control, doors and all switches inside the car.

Using standard graphic software, our laser etcher machines are programmed to remove layers of spray paint to exacting specifications and show sub-layers by removing dark layers (light blocks) to reveal the white or natural colour of the plastic beneath for backlighting purposes. Our lasers can laser-cut plastics, polyester, poly-carbonate, rubber, acrylics and other materials. Our laser machines have maximum etching area of 300 X 300 mm at one stretch.

+ Show more

- Show less

Hot Foil Stamping

Product Detail

Hot Foil Stamping

Hot stamping is a dry decorative process that transfers colour pigment or metallic material from a continuous film carrier sheet onto a component. The process utilizes heat and pressure to transfer an image to the plastic substrate. A silicone rubber die conforms to fit the intended surface profile and allows for excellent resolution and repeatability.

Our Hot stamping capability can make different kinds of hot stamping processes. Our engineers are expert in guiding the process from the tool design stage itself. We have capability to print parts up to 300 mm in length.

+ Show more

- Show less

Ultrasonic Welding

Product Detail

Ultrasonic Welding

ACT has 4 Ultrasonic Welding lines to meet specific customer requirements. Ultrasonic Welding is a great replacement for screws, glue, and snap-fit designs. Utilizing high frequency ultrasonic acoustic vibrations, ultrasonic welding generates a melting point between two materials to provide a consistent joint without the use of adhesives or other joining materials.Ultrasonic insertion has very low energy requirements, requires little to no cooling time, and uses no consumables. As such, it has a broad range of applications and is a cost-effective and environmentally friendly solution.

+ Show more

- Show less

Value added assembly

Product Detail

Value added assembly

Manufacturing of individual components to fully-assembled functional devices require a holistic approach to building products. We need to combine technology with expertise and wisdom in delivering the desired outcome.

Therefore, We understand and are committed to be a one point supplier who offer mix ‘n‘ match solutions to save customers both time and money. That’s why we offer an incredibly diverse range of capabilities to meet maximum requirements and demands with good quality.

+ Show more

- Show less

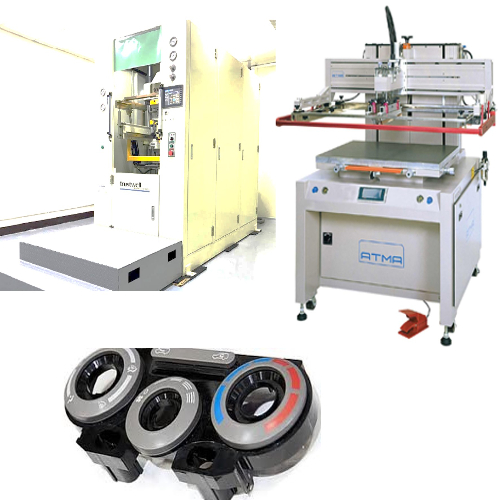

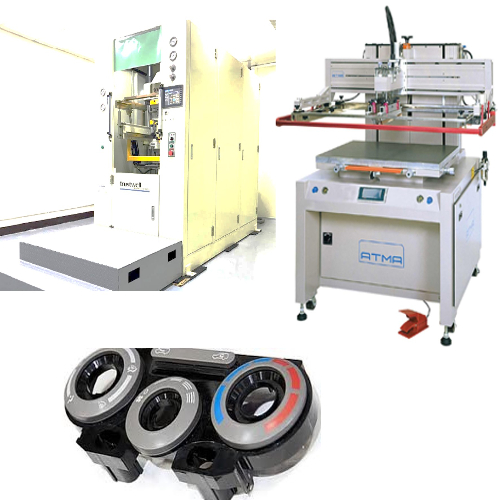

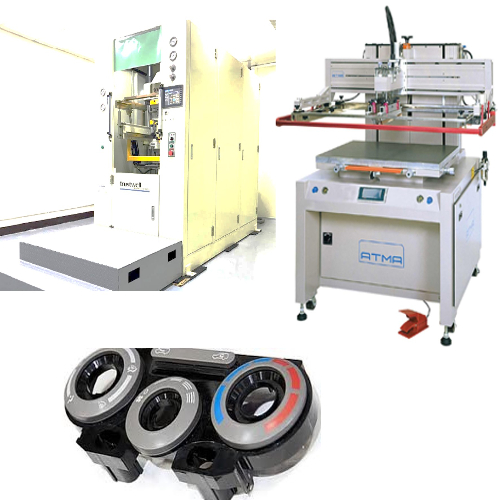

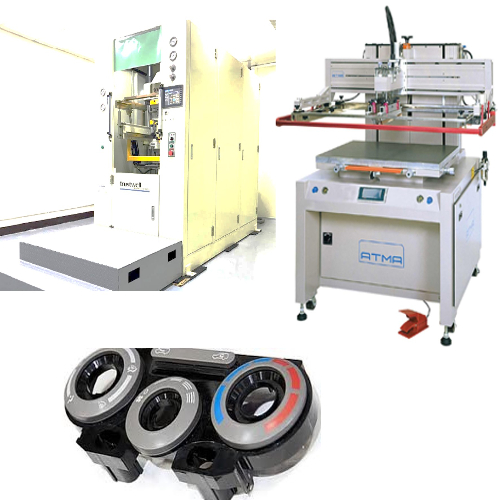

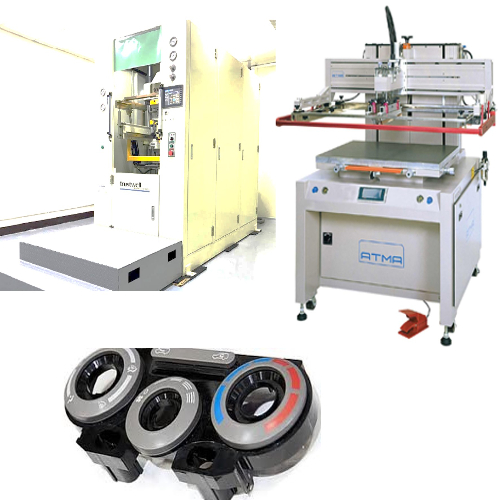

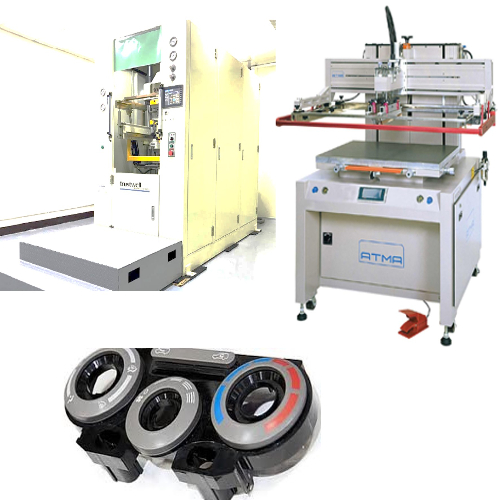

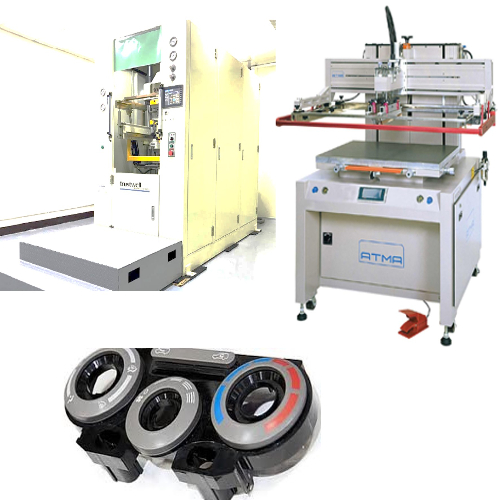

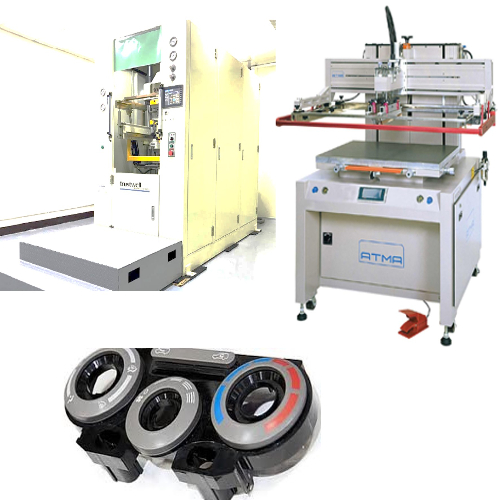

Screen Printing

Product Detail

Screen Printing

We at ACT have in-house screen printing advantage which is one of the most commonly used print options. It is a versatile type of printing for which the need is aplenty as many requirement demands that we use this technique.

Screen printing allows us to print on any thickness of plastic which is perfect for plastic molding parts and on applique. Colors are printed one at a time and can be matched with a pantone color code or to a customer supplied sample. Having this feature in-house reduce the effort of set-up times for screen printing elsewhere as the molded parts can be screen printed by ourselves and delivered together.

+ Show more

- Show less

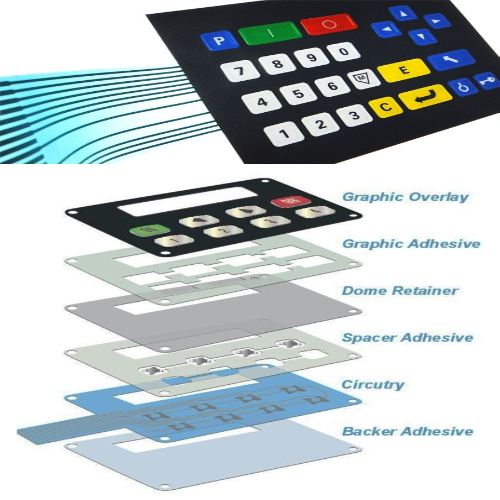

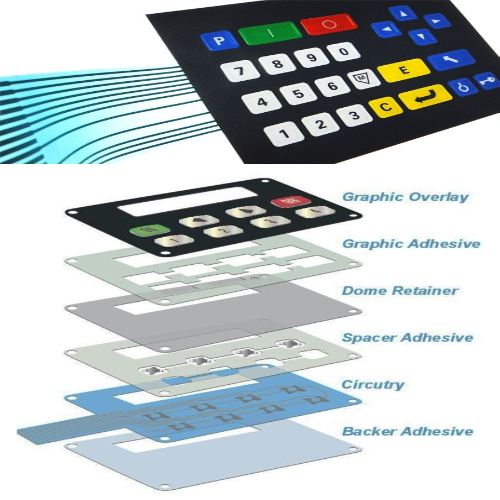

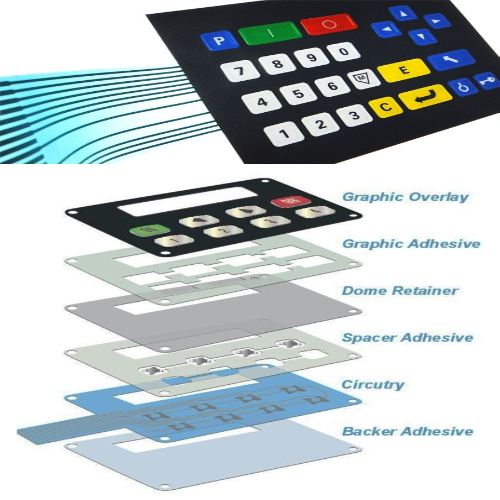

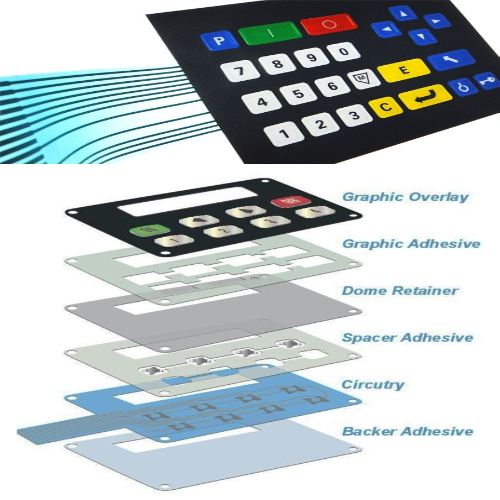

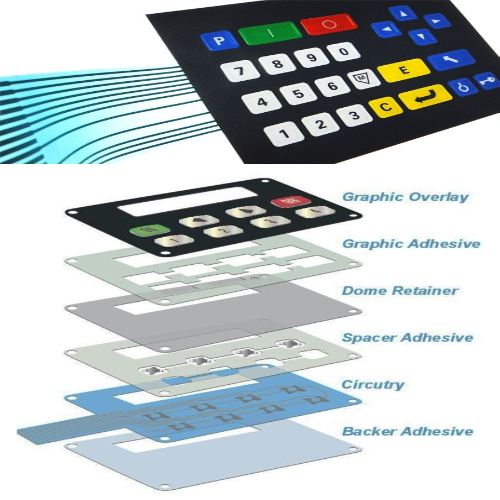

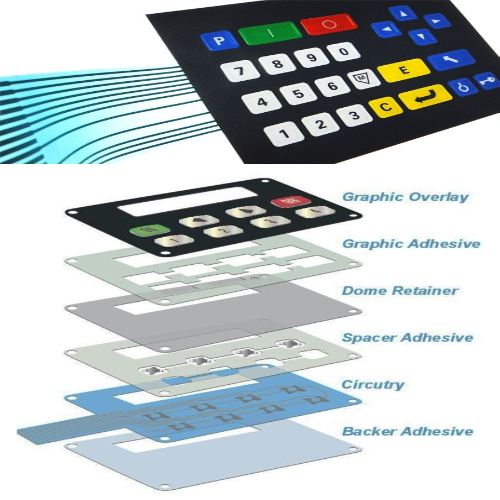

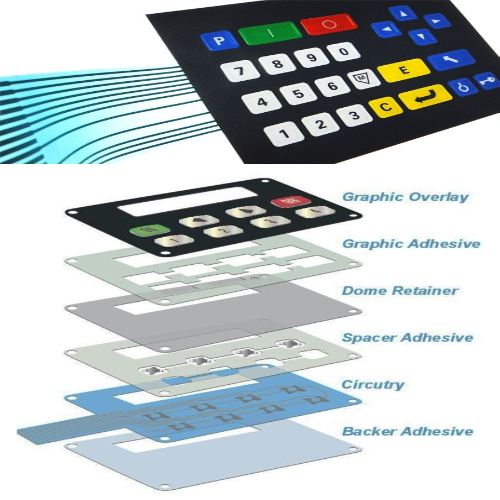

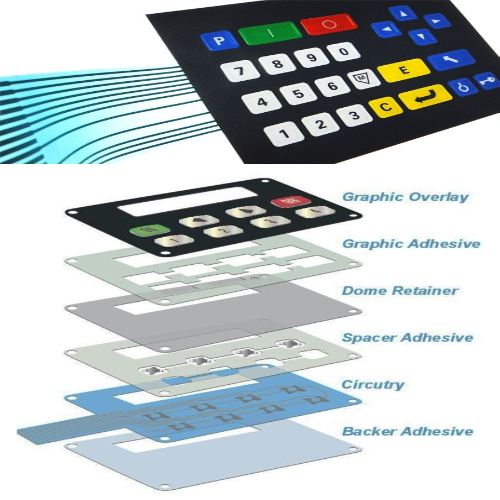

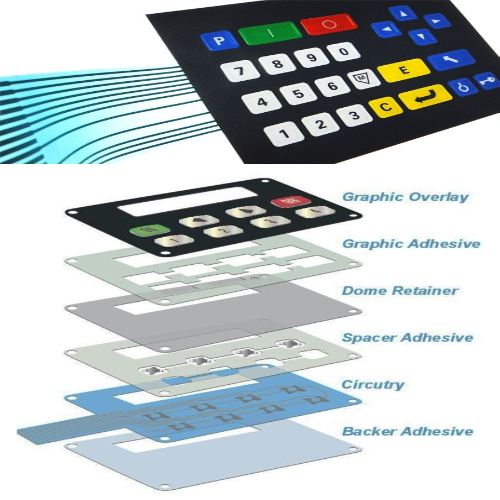

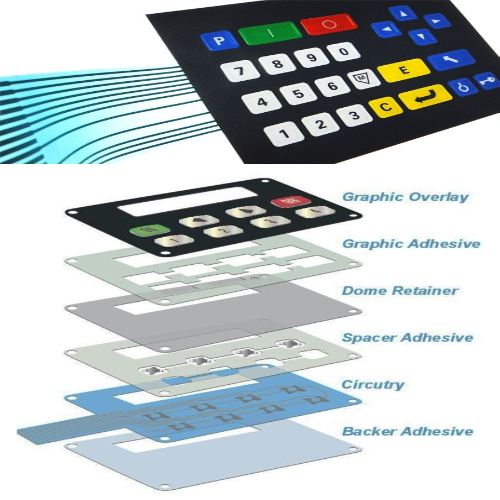

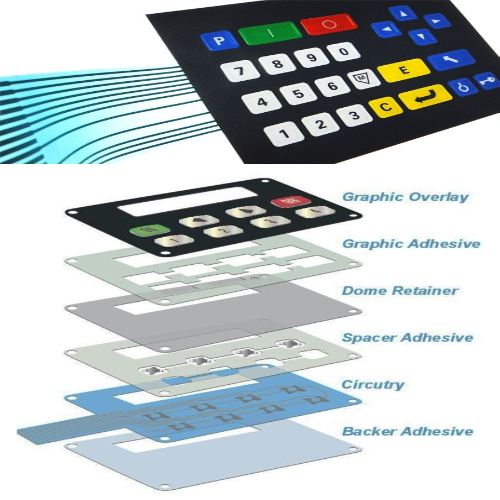

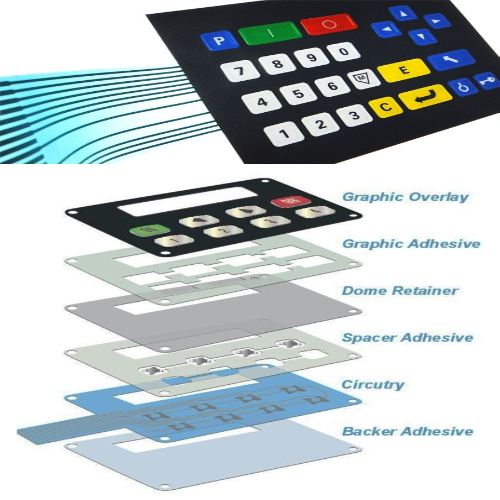

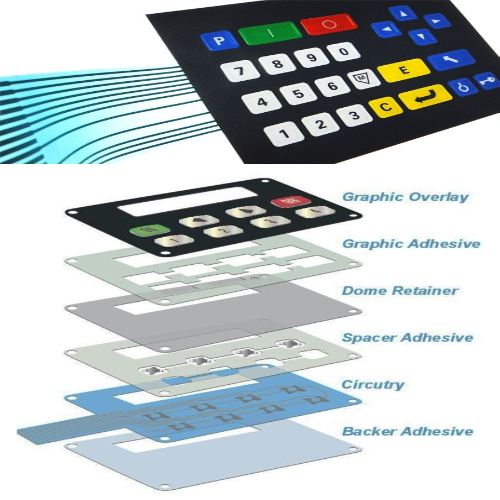

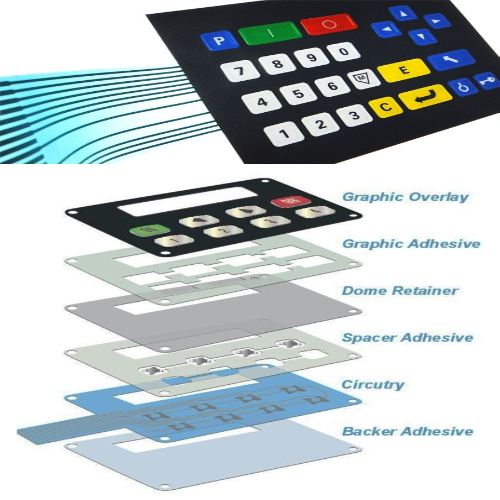

Membrane Switches

Product Detail

Membrane Switches

•Membrane Geeks on developing complex, integrated human-machine interfaces with unique functional, graphics with performance requirements.

•Extensive understanding about India US and Europe quality standard in membrane switch and related products.

+ Show more

- Show less

IN MOULD DECORATIVE

Product Detail

IN MOULD DECORATIVE

Combining the decoration process with the molding process adds durability; decreases manufacturing costs by eliminating post-molding labelling, handling and storage. It also enables design flexibility. IMD allows for a wide range of colors, effects, textures, and graphic options and can replicate stainless steel, wood grain and carbon fiber. IMD is commonly used on washers and dryers because of its affordability and durability.

We also take up projects that may need in-mold decoration (IMD) to include an image or coating on a plastic surface. This process involves printing a high-quality image on a heat-resistant plastic film that will hold up to the stress of in-molding. The printed film is inserted into the open plastic injection mold and held in place via vacuum ports or electrostatic charge while the mold is closed. Once closed, plastic resin is injected into the mold, encapsulating the label to the finished part.

+ Show more

- Show less

In mould labelling

Product Detail

In mould labelling

The technology where the preformed printed film is used during injection molding.

•This process achieves high-precision decoration of the three-dimensional surface.

•It is highly integrated, saving subsequent assembly processes with improved yield.

•The decorative pattern is built in, never worn out.

•Light transmission for easy and clear display functions.

•It is better, lighter, more solid, more choices, and more secure for end users.

+ Show more

- Show less

In mould electronics

Product Detail

In mould electronics

In-Mold Electronics eliminate additional weight and post-processing operations by allowing parts to be directly included in the electronic circuitry during the molding cycle.

It combines In-Mold Decorating (IMD) technology with Printed Electronics.

•IME allows to add functional parts even onto the complex plastic parts which is not possible in conventional laminating process

•IME surface decoration is possible with IMD/IML process

Eliminates printed circuit boards, light guides and make product look sleek and compact

+ Show more

- Show less

Chrome Plating

Product Detail

Chrome Plating

Modern engineered plastics are used in countless industries and applications throughout the world. These materials are popular for many reasons, including their versatility, easy machinability, and excellent surface finishes. However, because plastics are not electrically conductive, they are very difficult to plate with proper adhesion.

Electroplating is the process in which dissolved ions of one metal are deposited onto the surface of another substrate. Plastic plating is commonly used in many industries for purposes such as corrosion and wear protection, increasing surface hardness, promoting electrical conductivity, or for improving the appearance of a part or component. The process of plating metal onto plastic is now a widely accepted industrial practice that offers several crucial benefits for manufacturers everywhere.

Our electroplating projects have been described as having “excellent adhesion and RF performance” by our clients. This is important because many of the applications for plastic plating will be deployed in extreme environmental conditions, such as high temperature or high altitude/low-temperature ranges. At present we have a maximum of 1500mm X 1000mm plating area in a single dip in our plating line.

+ Show more

- Show less

View more

Our Offices

ACT PLAST PAINTS PRIVATE LIMITED Office 1

105/4, 5A Ezhichur Main Road, Ezhichur, Sriperumbudur Taluk, Kanchipuram District, Chennai - 603 204, Tamil Nadu, India., Chennai, Tamil Nadu, 603204 India

ACT PLAST PAINTS PRIVATE LIMITED Office 2

No.330/1C2, Block A/2 Shakthi Industrial Park Bangalore-Hyderabad Highway Near Hotel K9 , Anantapur, Andhra Pradesh, 515110 India

ACT PLAST PAINTS PRIVATE LIMITED Office 3

231/5A, Poothurai Main Road, Poothurai Village , Vanur Taluk, , Villupuram, Tamil Nadu, 605111 India