- Industrial Plants, Machinery and Equipment

- Seeds, Fertiliser, Pesticides and Agro-input chemicals

- Textile

- Engineering and Research

- Food Processing and Distribution

- Leather

- Fuel and Alternative Fuels

- Tool Kits, Hand Tools and Hardware

- Rubber, Resin and other Natural Polymers

- Glass, Glassware, Glass furnaces and other equipment

- Plastic and Synthetic Polymers

- Chemicals, Dyes, Solvents and Petrochemicals

- Manufacturing

- Engineering Services

- Metalworking and Fabrication

- Pharmaceuticals

What do you want to Enquire about?

About Us

Jindal Hydro Project Inc. is a quality-focussed company that offers hydraulic machines and solar services. We have a production team that sources base materials from reliable vendors to ensure quality of the finished products. We also maintain a huge stock of products in order to meet urgent market requirements. We are a client centric firm that ensures clients requirements are met with our products and services.

Jindal Hydro Project Inc was established by Mr. Rakesh Gupta in year 2013 with a small team of 15 experienced engineers. Over the years, we have grown multifold and have set up a modern manufacturing unit with latest machines and tools. Our manufacturing unit adheres to the prescribed GMP norms and follows environment protection and pollution control practices. Additionally, we have a packaging unit that is equipped with sophisticated packaging machines. The facility gives us flexibility to package products in bulk or individually as per the customers’ requirements. Moreover, we also have a R&D wing that constantly works towards improving quality of our product range and innovate production techniques.

Our range of machines includes metal plastic and paper scrap baler, shearing machines, shredders, hydraulic presses, baling press machine, solid waste compactors & shredders, power packs, hydraulic presses for various applications, hydraulic cylinders, etc. We offer service of customisation, using which clients can get the products designed by us as per their exact requirements and specifications.

View more

Our Leadership Team

Mr. Amit Gupta

Business Head

Mr. Rakesh Gupta

Business Head

Mr. AMIT GUPTA

Business Head

Products & Services

Hydraulic Cylinders

Product Detail

Hydraulic Cylinders

- Available in standard and custom-made specifications.

- Stroke capacity of the hydraulic cylinders:400 mm (maximum).

- Hydraulic products consist of carbon manganese steel or stainless steel piston rod, chrome or nickel plated rod, alloy steel or carbon steel fabricated tube, metal barrel and rod end port.

- Quality of these systems has been verified on the basis of UV leak detection testing, dynamic and static pressure tests.

+ Show more

- Show less

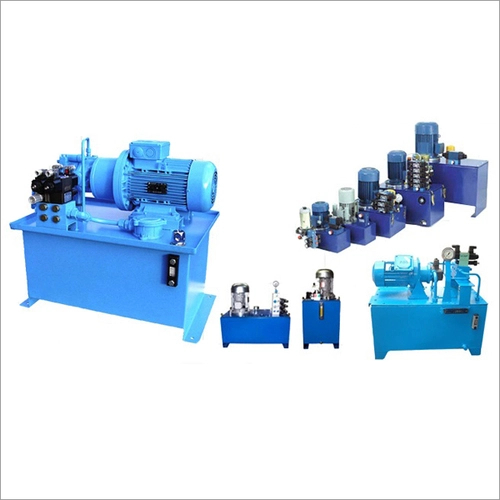

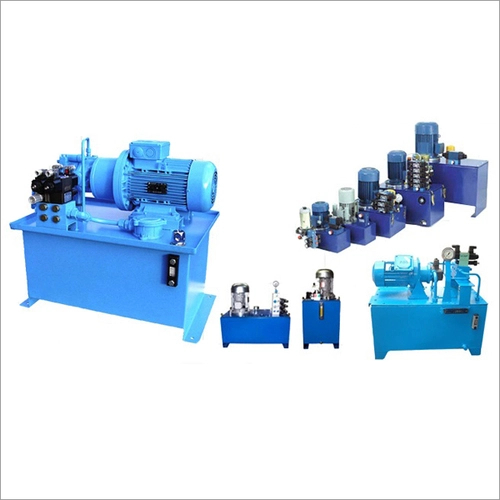

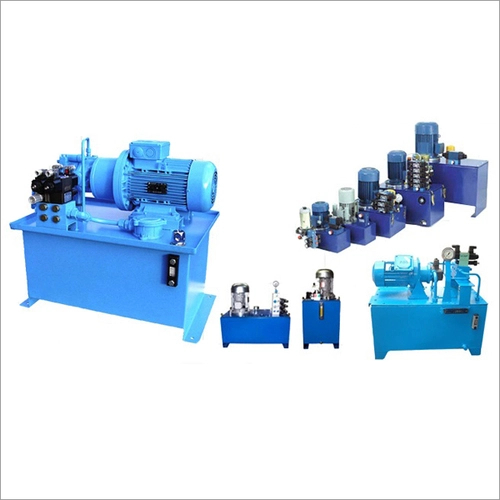

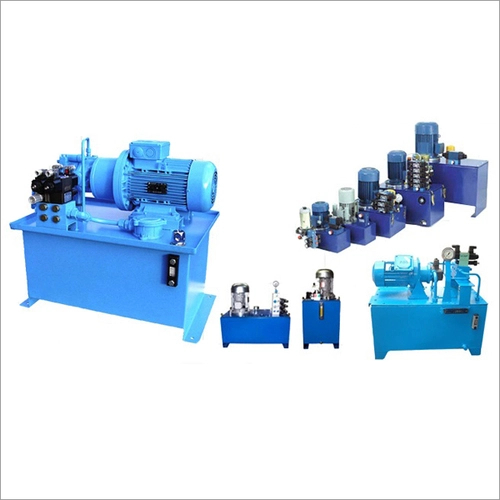

Hydraulic Power Pack

Product Detail

Hydraulic Power Pack

- Powered by electricity, the automatic power pack can be accessed with 7.5 hp to 100 hp power capacity and 700 bar (maximum) pressure range-based options.

- Equipped with powerful motor that helps to deal with leakage, overheat and overload related conditions Equipped with a cutting-edge pump for easy integration with single acting and double acting cylinders

- Actuator is easily movable

- Pressure calibration process is executed by its inbuilt low- and high-pressure revering valve

+ Show more

- Show less

Bricks Making Machine

Product Detail

Bricks Making Machine

- Uses fly ash, cement, sand, gypsum, lime sludge and stone dust as its raw materials

- Can produce 6000 to 20,000 pieces of bricks. Each brick weighing 300 grams

- PLC controlled mechanism guarantees zero error functioning

- Comprises of necessary parts like pallet truck, pan mixture, wooden pallets, wheel borrow, and conveyor Reduces labour cost, saves production time without affecting its output

- Eco-friendly operation

+ Show more

- Show less

Tablet Press Machine

Product Detail

Tablet Press Machine

- Stainless steel made

- Delivers standard quality, high output and automatic operation

- Option of pneumatic or hydraulic type mechanism

- High speed equipment is designed with dual outlets, touch screen with easy to comprehend operating mode, alarm system, force feeder loading and unloading arrangement.

- Advanced design of its turret helps to avoid cross contamination. Overload prevention section safeguards its punches against wear and abrasion.

- Worm gear box is equipped with transmission system which is lubricated to avoid abrasion and emission as well.

- Convenient to clean and maintain tablet pressing cabin or room

- Automatically ceases to function during overload

+ Show more

- Show less

Bagasse Baling Machine

Product Detail

Bagasse Baling Machine

Used for recycling of bagasse which is disposed after crushing sugar cane

- Can be operated in semi automatic, manual and automatic operating mode based options

- Capacity: 10 ton to 100 ton

- Computerized numerically controlled or non CNC operated equipment is preferred over its commonly available counterparts for its consistent operation, smooth bale discharging arrangement and real time display facility.

- Can endure high pressure and its structure

- Completely rust protected

- Control panel is equipped with replays and switches for signal delivery purpose

- Digital temperature controller helps to maintain necessary temperature for oil

- Safety features in sync with global norms

+ Show more

- Show less

Gallery(1)