What do you want to Enquire about?

About Us

Penny Grow has established itself as the go-to source for breaking technology services in wholesale and retail banking, capital markets, and insurance.

Established in 1999 & Pioneers in hard chrome surface treatments, developed infrastructure and skill base towards various type of plating surfaces including helical one, Today SunIndia is one of the leading reliable companies to trust for Chrome surface applications.

When it comes to the science of best range of industrial immersion heaters, SunIndia present smart, sturdy and sustainable heating solutions with vide range of tubular heater, immersion heater & coil heater of unmatchable experience and expertise for applications in Industries across the spectrum. We manufacture wide range of quality Heating elements for Plastic & Other Allied Industries.

|| We have a spacious factory essential for the production unit situated in Greater Noida, Uttar Pradesh India from where we manufacture and supply a large range of Immersion heaters.

We are a vertically integrated manufacturing and service company where starting from Design and Engineering of products to manufacturing of industrial components, assembly, testing and final finishing and packaging is done within our manufacturing facilities. This helps us in providing our customers with Top Quality, Competitively Priced Products delivered On Time to the customers. With sound technical expertise, large resource pool & experience manpower our company continues to maintain & exceed standards in terms of quality, customer satisfaction and timely delivery that are demanded by the process industries that we serve from so many years. A team of technically sound & dedicated engineers supported by well build infrastructure, we are committed to perform continual important role in polymer, plastic, injection molding and other critical manufacturing sectors that demands quality product and after sales services.

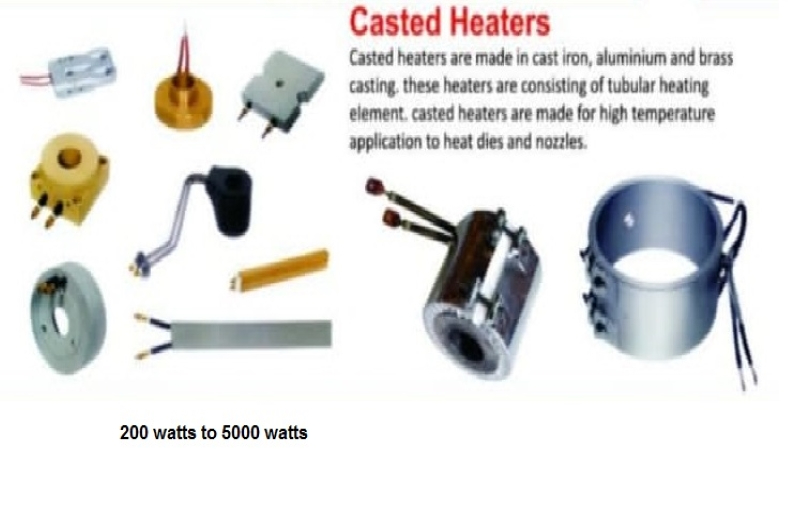

General purpose industrial heater, customized immersion heater, mica & ceramic band heaters, immersion, art ridge, chemical, water, air, casted heater, tubular, finned air heaters, cartridge heaters, immersion heaters, bobbins immersion heaters, alkaline, porcelain heaters, strip finned heaters, heating elements, thermocouple, ceramic band heaters, mica band heaters, oil heaters, air heater, Heat Tracing Cables and Thermocouple Cables. We are constantly exploring ways to improve our products together with maintaining “Quality and Customer Satisfaction” that is our prime objective. Recently, Sunindia also took over the manufacturing and technology rights of Alliance Heaters which was into developing and supply of heaters since 2007 having a large base of satisfied customers.

View more

Our Leadership Team

Mr. Sunil Kumar

Business Head

Products & Services

Hard Chrome Plating Service

Product Detail

Hard Chrome Plating Service

+ Show more

- Show less

.jpg)

Immersion Heaters

Product Detail

Immersion Heaters

Immersion heaters are a fast and efficient way of heating up various liquid solutions in processing equipment, large tanks and containers in many industries. Heating up liquids using direct heat transfer allows for the liquid medium to quickly reach the desired temperature using electric heaters. This application is commonly used in chemical processes, large petrochemical containers as well as large water containers that require fast heat up time. With minimal maintenance requirements, immersion heaters are an excellent solution to rapid heating in almost any industrial environment.

Flanged immersion heaters are high capacity electrical heating units made for tanks or pressurized vessels. They consist of multiple tubular heaters formed into hairpin and welded or brazed to flanges. The heating elements could be made of copper, stainless steel or Incoloy sheath. Variety of flange materials and shapes can be made available as per customer’s request. Various types of electrical protection housing, thermocouples and high limit switches can be incorporated.

Flanged immersion heaters can be used in different applications. In order to meet the heating requirements of a specific application and have a safe operation in the environment within which a heater operates several factors should be taken into consideration in the design of flanged immersion heaters.

+ Show more

- Show less

.jpg)

Finned Tubular Heaters

Product Detail

Finned Tubular Heaters

Finned tubular heater are the most common type of heating elements used for heating air and other gases. The fins along the tubular length assist in even heat dissipation. All elements have mild steel fins copper brazed to the tubular heating element sheath unless otherwise specified.

Duct heaters use fin tubular elements within its design to help reduce the watt density. It also allows for more consistent air flow streams within the duct and increases the life longevity of the elements.

In applications where tubular heaters are exposed to forced convection, placing fins around tubular heaters increases their surface area and thus improves their heat transferring capacity. Finned tubular heaters, compared to regular tubular heaters, run at lower surface temperatures for the same watt densities when placed in identical air streams.

Despite their advantages, finned tubular heaters are not recommended for applications where outlet air temperatures exceed 600°F.

The physical characteristics of a finned tubular heater play a major role in the effectiveness of its heat transfer.

Threaded fittings, if required, are the standard mounting attachments supplied with finned tubular heaters. These fittings are brazed or crimped onto the heaters. For special applications, finned tubular heaters can be made with mounting brackets that have special designs.

+ Show more

- Show less

.jpg)

Porcelain Heaters

Product Detail

Porcelain Heaters

Manufactured from high temperature bearing insulators, Porcelain Heaters offered are used in various industries. The Antique Porcelain Heater contains elements that are exposed partially in air for better transmission of heat. Porcelain Heater is extensively used in ovens, tanks where draining cannot be done to change the heaters. The Porcelain Heaters offered by us are known for their high precision, performance and durability. Porcelain Heater is constructed using several refractory ceramic blocks assembled together to the required length. The Nichrome wire heating element is inserted into the ceramic blocks, with a terminal block at one end.

This assembly is then inserted into a pre-assembled special protection tube, when used in liquid immersion and gas application. However, porcelain heaters can also be used in direct air-heating application without the protection tube.

FEATURES:

- Offers a large area to heat liquids or semi-solid materials like wax, fats, oil and bitumen

- Suitable for indirect heating of gases and liquids, where it is inserted into a pocket or protection tube in the process tank, wherein, it can be repaired or replaced without draining the process tank

- Wide range of lengths, voltages and power is available to meet customers’ specific requirement

ADVANTAGES:

- Simple and low-cost installation

- Ease of maintenance and repair

- Energy efficient as 100% of heat generated is within the solution

+ Show more

- Show less

.jpg)

Flexible Tubular Heaters

Product Detail

Flexible Tubular Heaters

The Flexible Tubular Heaters is latest innovation for Heating Manifolds in the most efficient manner. Easiest handling, simple assembly, improved thermal performance and the simple storage are some of the crucial advantages of the Flexible Tubular Heaters over the Traditional Manifold Tubular Heating Elements. Flexible Tubular Heaters eliminates costly downtime associated with waiting for a custom bent tubular heater. Flexible Tubular Heater is your best choice for immediate, durable, high performance replacement heaters.

The Flexible Tubular heaters compress into the groove and provide excellent heat transfer. Straight lengths available Ex-Stock eliminate costly downtime associated with waiting for custom bent tubular heaters. Engineered with a robust design incorporating greater thermal mass, our Flexible Tubular Heater is user-formable with a flexible solid casing that stays in the groove, yet is easy to install.

FEATURES:

- Easy installation with a uniform finish

- Can be formed by hand

- Stored in a straight condition to save storage space

- No special installation tools required

- Ground Breaking Technology ensures industry leading heat transfer

- Up to 75% sheath contact with Round and Square section heaters when recommended groove geometry is followed

- Rapid heat-up times

- Minimal temperature difference between heater sheath and heated tool

- 3-dimensional groove geometry possible

- Industry’s smallest bending radius

+ Show more

- Show less

.jpg)

Mini Coil Heaters

Product Detail

Mini Coil Heaters

Mini Coil Heater is manufactured in Two Standard Round Diameters of 1.5mm and 1.8mm. The Mini Coil Heater is swaged and compacted to these diameters and fitted into special clamps to tighten over circular parts for heating purposes.

Mini Coil Heater is manufactured in Two Standard Round Diameters of 1.5mm and 1.8mm. The Mini Coil Heater is swaged and compacted to these diameters and fitted into special clamps to tighten over circular parts for heating purposes. Sheath material available is Chrome Nickel Steel. The Flat diameter of 1.3 mm x 2.3 mm can also be made which is tightly coiled on a heat-conducting precision tube and encapsulated and thermally insulated by an outer lathing part.

The Mini Coil Heater clamping style is designed to save hours of downtime in moulds. The Mini Coil Heater is equipped with a special cover for easy fitment over circular parts.

+ Show more

- Show less

.jpg)

Ceramic Band Heaters

Product Detail

Ceramic Band Heaters

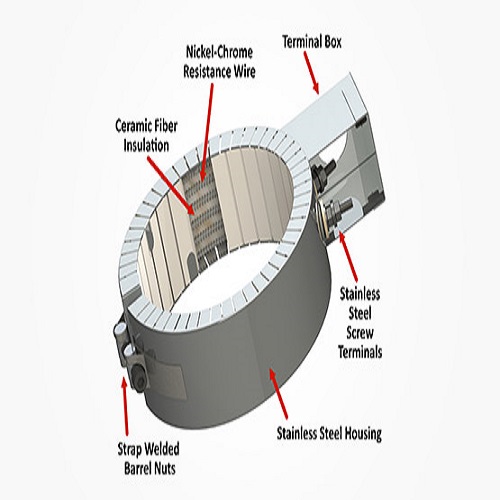

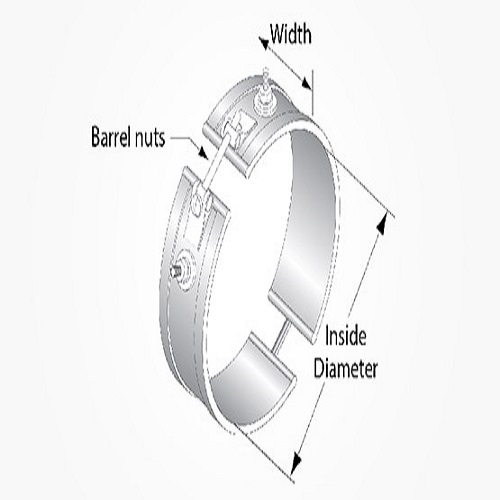

Ceramic Band Heaters were developed to meet industrial requirements for high-temperature long-lasting heaters. They are ideally suited to comply with today’s new resins, which call for ever-increasing process temperatures.

An additional advantage of the Ceramic Band Heaters is that they transfer heat through conduction and radiation. This makes their tightness on barrels less critical; thus they are less prone to thermal expansion problems.

Theoretically, there are no restrictions on the diameter that ceramic band heaters can attain; however, because these heaters utilize ceramic tiles that are available only in specific lengths, the width of these heaters falls within a certain incremental range of sizes.

Advantages:

- Built-in insulation minimizes the unwanted changes in temperature along the barrel

- Heat transfers through radiation, conduction, and convection, so a perfect fit is not required compared to other band heaters.

- Heat transfers are not affected by irregular surfaces or a loose fit

- Because they operate at higher watt densities, they can be used in wider increments

- The number of bands used can be reduced with simplified wiring

- The heater is safer with the cooler external surface – over other band heaters

- The flexible design allows easy installation and removal

+ Show more

- Show less

.jpg)

Ceramic Die Heaters

Product Detail

Ceramic Die Heaters

Ceramic Die Heaters are manufactured in two half’s & provided with spring loaded clamping system to provide an excellent grip of the heater mounted vertically. Heaters are provided with inside cover to protect against frequent dismantling of dies.

+ Show more

- Show less

.jpg)

.jpg)

Energy Saving Band Heaters

Product Detail

.jpg)

Energy Saving Band Heaters

Energy Saving Ceramic Band Heaters are Specifically designed and engineered to meet the ever increasing demand for energy conservation and to improve operation efficiency capable of generating higher temperature essential to process today’s high temperature resins.

Energy Conservation is achieved by using 1″ thick Ceramic fiber insulating blanket on the outer surface increasing the overall outer diameter by 2″(Minimum Length Required is 4″). Reducing power consumption upto 30% because of low thermal conductivity of the ceramic fiber insulation, the external surface temperature of the insulation plus ceramic band heater is approximately 80°C while running the inside surface temperature at 300°C

FEATURES:

- Saving Energy Up to 30%

- Reduce Wattage of Heater

- More Uniform Heating

- Less Downtime increases Productivity

- Reduced Preheating time of Machine

- Heater cost is recover in shorter time

- Cool working atmosphere for operator

- Overall Outer diameter increases by 2″ (50 mm)

+ Show more

- Show less

High Density Cartridge Heaters

Product Detail

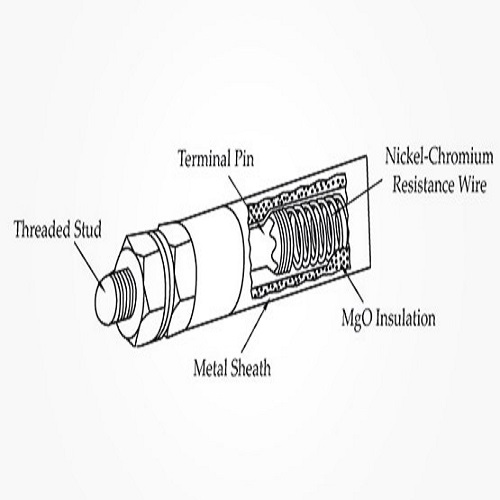

High Density Cartridge Heaters

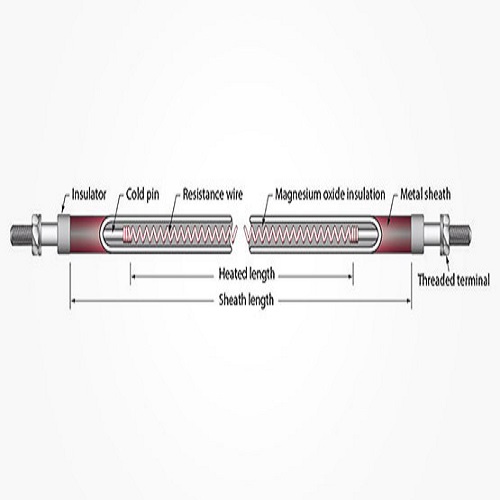

High Density Cartridge Heater can be considered “Component Heaters” that are used to heat up many different applications. Primarily used in moulds, dies & sealing bars, this Cartridge Heating Element fit snug inside a cavity and helps heat solids by reaching high temperatures. High Density Cartridge Heater has the versatility of being able to carry thermocouple inside to help control temperatures of the heater more accurately. Various diameters allow for the Cartridge Heating Element to be used in any cavity and can be custom designed with any cold section. Lead wires extend from the end to your controls.

High Density Cartridge Heater distinguishes itself by its high compression and therefore especially efficient heat emission. That’s why such Cartridge Heating Element is produced with a ground surface for a H7 fit.

The construction of High Density Cartridge Heater positions a nickel-chrome resistance wire precision wound around a magnesium oxide core. It is inserted into a Stainless or Incoloy tube locating the resistance wire close to the sheath. The core is centrally positioned within the tube and filled with magnesium oxide powder. Nickel pins pass through the centre of the core making contact with the resistance wire at both ends. The whole assembly is highly compacted by a swaging operation and thus ensuring excellent heat transfer to the external sheath.

+ Show more

- Show less

.jpg)

Sealed Mica Nozzle Heaters

Product Detail

Sealed Mica Nozzle Heaters

Sealed Mica Nozzle Heaters are hermetically sealed for liquid plastic during the manufacturing process. The connection between the heating element and the leads is protected by a special fitting made of 1 mm thick brass or stainless steel, without welding which allows a high mechanical strength in the most delicate area of the heater.

During manufacturing, the Sealed Mica Nozzle Heaters are submitted to extremely high pressure that ensures high insulation, excellent thermal exchange, lack of internal voids, perfectly smooth contact area for an optimum and uniform heat transfer to every part of the nozzle.

The Sealed Mica Nozzle Heaters are available in either Brass or Stainless Steel versions, depending on the application. It is recommended to use stainless steel nozzles where the molding or extrusion of PVC is involved as stainless steel will withstand the corrosive fumes far better.

The Sealed Mica Nozzle Heaters are a rugged product that resists very well to wearing and shocks. The inner profile is perfectly round, providing a perfect coupling with the nozzle. Size of the connecting cap is minimal, giving extremely limited overall dimensions. Power connection is performed by a Standard metal braided cable with Length of 1000 mm.

A thin layer of the “high” thermal conductive MI material is used to electrically insulate the element wire from the inside diameter of the heater sheath.

+ Show more

- Show less

.jpg)

Coil Type Nozzle Heaters

Product Detail

Coil Type Nozzle Heaters

Coil Type Nozzle Heaters are capable of performance under the most adverse conditions. Highly recommended for processing high-temperature resins to eliminate premature failures due to burn out/ process material leakage.

Heat transfer is based on conduction as well as on radiation principle, which not only improves the thermal efficiency but easy to assemble on nozzles as no pressure on heating surface is essential. Even unskilled operator can fit the heater with no risk of failure of the heater.

Coil Type Nozzle Heaters are specially designed to prevent the failures of heaters against the leakage and contamination of plastic material at nozzle position. This heater can meet the higher temperature requirement prior to molding at the nozzle position.

Stainless Steel Sheath Tubular Heating Elements in Round / Flat Sections are used as Heat Source. Low thermal expansion steel covers with suitable Mounting Brackets houses these Tubular Heating Elements.

The Coil Type Nozzle Heaters are typically used to Heat up the Nozzles of Injection Molding Machines.

+ Show more

- Show less

.jpg)

Mica Band Heater

Product Detail

Mica Band Heater

Mica Band heaters are efficient and economical solutions to the heating requirements of many applications. Mica Band heaters can attain a maximum sheath temperature of 900°F, but with different electrical termination styles, clamping mechanisms, and ability to accommodate holes and cutouts, mica band heaters are successfully used in many applications, but are mostly sought for in the plastics industry.

The Mica Band Heaters made by Anupam utilizes different types of Top Grade Mica. The thickness of each mica layer is carefully selected in order to balance between the insulating characteristics of mica and the ease of heat transfer from the heating core to the machine barrel.

The resistance wire ribbon used in the mica band heater is not restricted to the capabilities of Nichrome wire. Different alloys are considered for different applications. The internal winding is carefully designed to ensure uniform heat distribution throughout the band heater. To maximize the surface-to-surface contact, our mica band heaters are carefully rounded and formed to optimize the grip on a machine barrel. The external metallic protective sheath of Anupam’s Mica band heaters is made of a special alloy, which expands less than the barrel when heated. This difference in thermal expansion makes the heater grip the barrel firmly once it is energized. This improves heat transfer which extends the life of the mica band heater.

+ Show more

- Show less

.jpg)

Aluminum Cast Band Heater

Product Detail

Aluminum Cast Band Heater

The liquid cooling function of the Cast Band Heater is of primary importance in maintaining the proper temperature of the barrel in the extrusion process. Extrusion machines differ from injection molding machines in that they often require heating and cooling. Cooling is required on extruder barrels to offset heat generated by frictional shear as the screw pump pushes plastic melt through the barrel and die head.

The Cast Band type comes with Water Cooling system & without Water cooling system. The Cast Band Heaters uses aluminum, an excellent heat conductor, to deliver a very uniform heat pattern on the barrel.

All Aluminum Cast Band Heaters are customized. The Tubular Heating element is embedded in the Aluminum Cast Band Heater & machining is to be done to get the required size.

High Thermal Conductivity provides uniform temperature. The main application of these heaters is in the Extruders.

ADVANTAGES:

- Gravity moulding ensures an excellent material homogeneity and thus a perfect heat transfer

- Constant surface temperature is achieved through appropriate forming

- As this is indirect heating, the heating resistance is protected. The solid or fluid to be heated is not in contact with the resistance

- High protection against corrosion

- The end-to-end control of the design and production chain allows us to deliver a product which suits your process perfectly

- Resistance in severe industrial surroundings (impacts, vibration)

+ Show more

- Show less

.jpg)

Air Cooled Ceramic Band Heaters

Product Detail

Air Cooled Ceramic Band Heaters

Air Cooled Ceramic Band Heaters are designed for super-efficient and economical cooling on extrusion and blow molding machines.

The heater band is 60% open by a perforated metal sheet which ensures maximum surface exposure for better cooling. The heater band is covered with Blower cover for mounting the Blower. Advantages of air cooled over liquid cooled operation includes lower cost, easy replacement, low maintenance, no leakage problem and uniform temperature control.

Historically, liquid cooled Cast-In Heaters have been the more frequently employed method of controlling the melt temperature of extrusion barrels. There is no doubt about the effectiveness and speed of liquid cooled castings in removing heat from the extrusion process. However, there are a number of drawbacks that primarily relate to maintenance-associated issues. Air Cooled Band Heaters are virtually maintenance free and therefore, when properly installed and applied, have the capability to far outlast their liquid cooled counterparts. Since cooling tubes are not used, the possibility of breakage, cracking or becoming clogged with brine or mineral deposits is not a concern.

+ Show more

- Show less

.jpg)

Mica Strip Heaters

Product Detail

Mica Strip Heaters

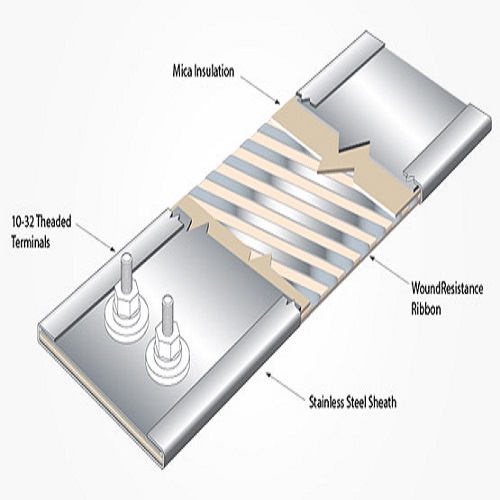

Strip heaters, often considered component heaters, are a simple way of using surface area to transfer heat effectively. A fairly inexpensive way of heating surfaces or small areas, strip heaters are an excellent solution to meet any budget. If strip heaters are used as a radiant heater, they have can have fins to maximize surface area and heat transfer to the air.

Mica Strip Heaters are constructed by winding a nickel-chrome resistance ribbon around mica insulation and encapsulated in a stainless steel sheath. They are available in an extensive variety of sizes and shapes with options for holes, notches and cut-outs. A number of threaded terminals, wire lead options and terminal boxes offer great flexibility for field wiring. These heaters are ideal for plastic processing applications and for anywhere heat is needed on a flat or curved surface.

FEATURES:

- Heat up time is fast to provide a quick response to control input

- The flat inner resistance ribbon generates a broad area of overall heat to put the heat source close to the work

- Quality assembled winding and spacing of ribbon ensures maximum heat transfer and heater longevity

- The Stainless Steel sheath is treated so that the surface allows the increase of heat transfer to retard oxidation

- The Mica insulation also withstands high voltage temperatures, resist moisture, and remain immune to most chemicals

- The Aluminized Steel sheath is rust resistant, durably rigid, and generates heat well

+ Show more

- Show less

.jpg)

Ceramic Infrared Heaters

Product Detail

Ceramic Infrared Heaters

Ceramic infrared heat elements are efficient, robust heaters which provide long wave infrared radiation. The ceramic heaters and infrared heaters are used in a diverse range of industrial and engineering applications such as thermoforming heaters, packaging and as heaters for paint curing, printing and drying. They are also used very effectively in infrared outdoor heaters and infrared saunas. Ceramic elements produced by Anupam include ceramic trough elements, ceramic hollow elements, ceramic flat elements, and can be customized as per drawings.

Ceramic elements operate in the temperature of 300°C to 700°C (572°F – 1292°F) producing infrared wavelengths in the 2 – 10 micron range. Most plastics and many other materials absorb infrared best in this range, which makes the ceramic heater the most popular infrared radiant emitter on the market. A range of aluminized steel reflectors are also available to ensure the maximum amount of infrared radiation is reflected forward to the target area.

The element wire of Ceramic Infrared Heater is embedded in glazed refractory which protects the wire from atmosphere to get longer life. In normal operating condition the life of the heater for most application would be well in excess of 10,000 hrs of 80% power. These are available with built in J or K Type Thermocouple or without Thermocouple variants in Yellow, White & Black colors.

+ Show more

- Show less

.jpg)

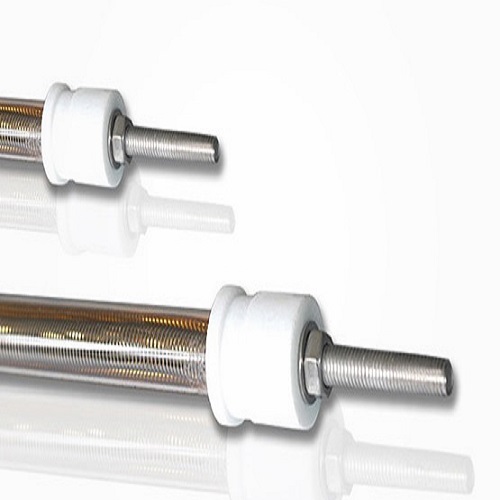

Medium Wave Quartz Infrared Heaters

Product Detail

Medium Wave Quartz Infrared Heaters

Medium Wave Quartz Infrared Heaters are excellent for surface heating and for drying coatings paint, dyes, lacquers, adhesives and in the processing of plastic sheet and films. They are available in Clear or Opaque Quartz Tube with gold or ceramic reflective coatings that focus the emitted energy onto the substrate.

The filament temperature of a medium wave emitter is from 850°F and 2150°F (454°C – 1177°C). The majority of energy generated by the medium wave lamps is in the range of the electromagnetic spectrum between 2-4 microns.

Medium wave emissions do not penetrate as deep into substrates as shortwave. The emissions are readily absorbed by water films, plastics and many solvents.

Medium Wave Quartz Infrared Heaters are slower in response to changes in process requirement as compared to the short-wavelength lamps and are slower to heat up and cool down.

Because of their long life, medium wave quartz infrared heaters perform extremely well in continuous processes. Medium wave infrared heaters are sold as individual heat sources or wired together in multiple emitter cassettes also known as IR Modules. The Standard End Connection in the Medium Wave Quartz Infrared Heater is the Screw Connection with Ceramic Cap to Protect the Terminals.

+ Show more

- Show less

.jpg)

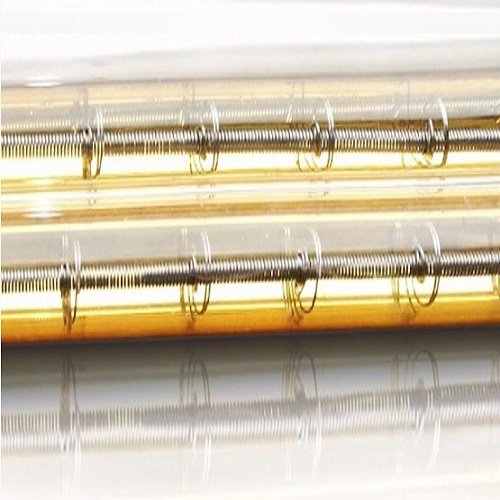

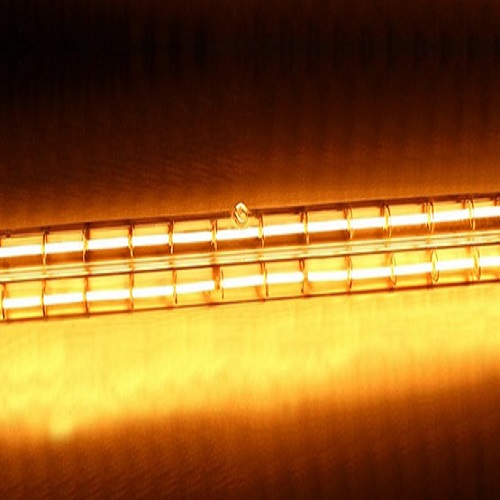

Shortwave Infrared Heaters

Product Detail

Shortwave Infrared Heaters

Short wave quartz infrared heaters are used in various industrial applications. It contains tungsten filament, helically wound, encased in quartz envelope. Tungsten as resistive element is capable of generating temperature in excess of 2750° C. Its response time is very rapid in 1 second it emits over 90% of IR energy. It is by products free & pollution free. Heat focus is very accurate due to compact and narrow diameter of IR tubes. Short wave IR element has maximum heating rate of 200W/inch.

The quartz envelope allows transmission of IR energy and protecting the filament from convective cooling and corrosion. Addition of small percentage of halogen gas in it not only increases life of emitter but also protects blackening of tube and depreciation on infrared energy. The rated life of short wave infrared heater is around 5000 Hrs

Short Wave Infrared Heater transmits heat in the form of electromagnetic waves at a velocity of approximately 3,00,000 Km/Sec i.e., at the speed of light.

These lamps are not only the fastest in transmitting heat but are most suitable for specific applications involving vacuum technology and dust free (clean room) conditions.

Infrared heat is particularly economical on energy compared to other heat sources because it acts quickly, directly on products. Short Wave Infrared heaters are suitable for all applications in which the attainment of high temperatures in the shortest possible time is what counts.

+ Show more

- Show less

.jpg)

Low & Medium Density Cartridge Heaters

Product Detail

Low & Medium Density Cartridge Heaters

Low & Medium Density Cartridge Heater is developed for heating applications not requiring high watt densities and sheath temperatures not exceeding 300°C. These Cartridge Heating Elements are designed in maximum watt densities of 30 to 45 watts per square inch depending on applications. Such a Cartridge Heating Elements of various sheath diameters can be used in any assembly, equipment or machine.

The Low & Medium Density Cartridge Heater can be absolutely customized to suit customer’s needs. Such Cartridge Heating Elements can be an economical option for customers not requiring high process temperatures. Cartridge Heating Elements are designed & calibrated perfectly to ensure that optimum conductivity between the resistance coil and the Cartridge Heater is achieved.

The Low & Medium Density Cartridge Heater design consists of a helically wound resistance coil made from nickel-chrome wire, evenly stretched and strung through holes in a round ceramic insulator. The element assembly is inserted into a Chrome Nickel Steel. This alloy provides the best combination of physical strength and resistance to heat oxidation up to 450°C.

Specially selected grain size and high purity magnesium oxide is used to fill all remaining space inside the ceramic insulator to increase thermal conductivity, dielectric strength, and provide longer operating life of the Cartridge Heater.

+ Show more

- Show less

.jpg)

Micro Tubular Coil Heaters

Product Detail

Micro Tubular Coil Heaters

Micro Tubular Coil Heater is a small, linear heating element that can be formed into different shapes and configurations. Also known as a Hot Runner Heater for its extensive use in Hot Runner Systems, the Micro Tubular Coil Heater is a high performance heater which allows high wattage in a limited space.

The ability to shape a Hot Runner Heater when cold enables to heat up parts with different shapes. During coiling, the gap between turns of coil can be modified to compensate for the heat losses at each end of the coil or to insert the heating element into slots.

Micro Tubular Coil Heater has a larger cross-sectional area and is thus capable of greater power than Micro Coil Heaters. For this reason the Hot Runner Heater is used in hot runners with adequate space and where high heat densities are required. Micro Tubular Coil Heater can accommodate type “J” or “K” thermocouple sensors.

Since the measurement point of a built-in thermocouple is situated in the Hot Runner Heater and never where the heat is actually required, our Micro Tubular Coil Heater with a thermocouple makes particular sense where the application allows the use of larger processing temperature or where the installation location or the design requires protection against overheating. The standard connection for our Micro Tubular Coil Heater is a 1000 mm PTFE-insulated lead wire with a Fiberglass sleeve with protective earth conductor lead.

+ Show more

- Show less

.jpg)

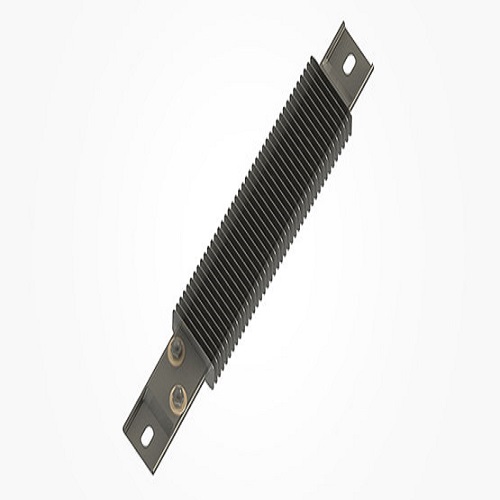

Finned Strip Heaters

Product Detail

Finned Strip Heaters

Finned Strip Heaters are used for both forced (mounted in a duct) and natural convection air heating (mounted at the bottom of cabinet type ovens).

Fins increase the heat transfer surface area to allow higher wattages than standard Strip Heaters. These are intended to be operated with a substantial airflow and are typically used in heating tunnels, dryers or any application that requires a hot air source.

Finned strip heaters, often considered component heaters, are the electric heating element that maximizes heat intensity and transfers effectively in an area. Steel fin strip heaters are an excellent industrial heating product that can be easily controlled by using a heating control panel, mechanical thermostat or cost effective bi-metal thermostats that can be installed on the surface of the heater.

Mounting holes are useful to mount the heaters securely on the wall housing with terminal extending from the sheath for easy electrical connections. Many users also request lead wires that extend from one end that make the installation more flexible as the temperature controller is easily adaptable to this configuration.

A finned strip heater is filled with highly-compacted MgO insulation which conducts heat from the nickel-chrome element wire to the outer sheath. The fins are spaced in a way that maximizes surface contact so that heat is displaced, and then transferred into the air faster.

+ Show more

- Show less

.jpg)

Ceramic Strip Heaters

Product Detail

Ceramic Strip Heaters

Ceramic Strip heater provides the ability to withstand higher temperatures . Anupam’s Strip heaters, often considered component heaters, are a simple way of using surface area to transfer heat effectively. A fairly inexpensive way of heating surfaces or small areas, strip heaters are an excellent solution to meet any budget. If strip heaters are used as a radiant heater, they have can have fins to maximize surface area and heat transfer to the air.

Our Ceramic Strip Heaters are dependable and reliable flat heating elements – designed to provide efficient heat to flat surfaces from common to industrial applications. The seamless sheath design of Ceramic Strip Heaters makes them ‘dimensionally’ stable in milled slots.

Ceramic Strip Heaters are constructed with ceramic insulation that quickly conducts heat from the resistance wire to the sheath resulting in low internal temperatures and long heater life in the most demanding applications. Precise placement of the resistance wire provides uniform sheath temperature across the width and along the entire heated length. This is an extremely rugged construction capable of high temperatures and high watt densities.

The inner construction consists of a wound nichrome resistance coil. The inner flexible wire is strung through ceramic insulator pieces. The coils are attached to the screw terminals, or high-temperature lead wires, for a positive connection.

+ Show more

- Show less

.jpg)

Micro Coil Heaters

Product Detail

Micro Coil Heaters

Micro Coil Heater is a high performance heater for smaller diameter Nozzles and Nozzle Tips that can also be formed in grooves to create three dimensional heating applications. Owing to their small cross-sectional dimensions, Micro Coil Heater is most often connected at both ends and do not permit the integration of a thermocouple.

The Controlled atmosphere annealing at the end of the manufacturing process allows the bending of this type of Micro Coil Heater into very complex shapes with an extremely narrow bending radius. Passing through this process helps the Micro Coil Heater have total flexibility in the distribution of heating density on the whole surface of the heated body.

To ensure that the standard 1000 mm PTFE-insulated connection cable can be positioned at one end, despite the standard two-ended connection of the element, in most cases the Micro Coil Heater is formed into a hairpin shape and wound in a parallel format. Our unformed Micro Coil Heater is also supplied in the hairpin bend shape as standard. Micro Coil Heater solves heating problems, where space is limited.

+ Show more

- Show less

.jpg)

Pressed in Brass Coil Heater

Product Detail

Pressed in Brass Coil Heater

Pressed in Brass Coil Heaters deliver the benefits of Cast In Brass Coil Heaters and eliminate known problems associated with the casting process. Originally designed for the mass spectrometry market, Anupam’s Pressed in Brass Coil Heaters have measured 8% faster responding than cast in brass heaters. The machined path in the brass for the heater enables exact repeatability of heat profile. By never exposing the coil heater to molten brass there are no risks of shifted heater coils, or destruction of the thermocouple junction.

Flexible design options include internal, external “wound in” or external slotted type J or type K thermocouple. For OEM applications Anupam can heat profile a Pressed in Brass Coil Heater specifically to your nozzle.

Features & Advantages

- Flexible cold section

- Higher Watt Density than a Coil Heater

- Resistance wire centered for more repeatable heat profile

- Sealed transition head for moisture resistant applications available

- Quick Heat Dissipation, High Insulation, Extended service life of heater.

- Can be built with a micro, mini, flat, low profile or round coil heater.

- Faster responding heater due to eliminated air pockets than Cast in Brass Nozzle Heater

- Profile and heater orientation precisely repeatable

- Improved Durability as Thermocouple is not exposed to molten brass temperatures

- Potential for designing thin walled brass heaters to minimize OD impact

- Precision fit on Hot Runner Nozzles

+ Show more

- Show less

.jpg)

Mini Coil Heaters

Product Detail

Mini Coil Heaters

Mini Coil Heater is manufactured in Two Standard Round Diameters of 1.5mm and 1.8mm. The Mini Coil Heater is swaged and compacted to these diameters and fitted into special clamps to tighten over circular parts for heating purposes.

Mini Coil Heater is manufactured in Two Standard Round Diameters of 1.5mm and 1.8mm. The Mini Coil Heater is swaged and compacted to these diameters and fitted into special clamps to tighten over circular parts for heating purposes. Sheath material available is Chrome Nickel Steel. The Flat diameter of 1.3 mm x 2.3 mm can also be made which is tightly coiled on a heat-conducting precision tube and encapsulated and thermally insulated by an outer lathing part.

The Mini Coil Heater clamping style is designed to save hours of downtime in moulds. The Mini Coil Heater is equipped with a special cover for easy fitment over circular parts.

+ Show more

- Show less

.jpg)

Thermocouples

Product Detail

Thermocouples

We produces top-of-the-line temperature sensing devices also known as Thermocouples. A thermocouple is a sensor for measuring temperature. It consists of two dissimilar metals, joined together at one end. When the junction of the two metals is heated or cooled a voltage is produced that can interpreted by a temperature controller, high limit or display device. There are two common constructions for these: Tube and Wire and Mineral Insulated. The tube and wire uses an empty stainless tube with a wire inside which has a welded tip incorporating the wire junction. This construction is typically used to 480ºC. The Mineral Insulated construction uses a highly compacted stainless sheath with solid conductors encased in magnesium oxide insulation. This construction offers a wider variety of diameters, allows for the sensors to be bent in the field and for temperatures to 1200ºC. These sensors are available is a huge range of physical packages with a variety of lead wire, housing, and mounting options.

In Mineral Insulated (MI) thermocouples, elements are surrounded by compact inorganic insulation (MgO) and housed in stainless steel or heat resistant alloy sheath to protect it from environment. MI thermocouples have a lot of advantages as compared to conventional beaded thermocouples. These thermocouples are available in long lengths which can easily be wound into coils making them easy to transport. They can be flattened or bends without affecting the sheath or the cores.

+ Show more

- Show less

.jpg)

Manifold Tubular Heaters

Product Detail

Manifold Tubular Heaters

Manifold Tubular Heating Elements provide for an economical, robust, and versatile heat source. These elements are commonly used to fit into milled grooves for hot runner molding systems. The precision fit optimizes heat transfer to the working surface. Our skilled benders and specialized bending equipment allow us to bend complex shapes. The Manifold Tubular Heating Elements are Custom Designed.

The helically wound heating element is made out of high-temperature resistance NiCr wire. This element is being insulated with high-temperature grade Magnesium Oxide Powder. As the Heaters are swaged and annealed at high sheath temperatures, they carry excellent electrical insulation and high heat transfer rate.

Precise forming of the heater is required for it to fit properly into the groove in the mould. To ensure this fit, we normally use a template as an inspection tool in the forming process. This Template can be supplied by the customer and manufactured as per the Customer’s design

The Manifold Tubular Heating Elements are available in Round diameters of 6.5 mm, 8 mm & 8.5 mm and in the Square diameters of 6 mm x 6 mm & 8 mm x 8 mm. Apart from this, other diameters can be custom manufactured as per Customers drawings.

To Manufacture the Manifold Tubular Heater, it is necessary to have an accurate drawing showing all the Center Distances, Bending Radius & Bending Degree

Manifold Tubular Heaters are tested for Insulation Test, High Voltage Test & Leakage Current Test.

+ Show more

- Show less

.jpg)

Tubular Heaters

Product Detail

Tubular Heaters

Tubular Heaters are custom-formed in a wide variety of shapes to correspond to your requirements.

Tubular heaters can be used in almost any application. Straight Tubular Heaters can be clamped to metal surfaces or inserted in machined grooves for conductive heat transfer. Or use a formed Tubular to provide consistent heat in any type of special application. Tubular Heaters may be clamped, immersed in liquids, cast into metal or spaced away from the work as radiant heaters. They may also be positioned in ducts or vessels for heating air or other gases.

Tubular Heaters of proper rating, material and shape can be used in most heating applications requiring process temperatures up to 750o C (1382o F).

Tubular heaters use 80% Nickel 20% Chromium high grade coiled resistance wire as a heating core. This core is welded at both ends to pins that provide a cold section that varies in length depending on the application requirements. The coil-pin assembly is precisely centred inside a heavy gauge, oversize metal tube, and embedded inside a 96% pure, high-grade MgO insulating medium. This assembly is then compacted through a roll-reducing process that reduces the outside tube diameter to its final size, and transforms the MgO matrix into a rock-hard solid that acts as an excellent heat transferring medium, as well as an electric insulation with high dielectric strength.

+ Show more

- Show less

.jpg)

View more

Gallery(5)