- Seeds, Fertiliser, Pesticides and Agro-input chemicals

- Textile

- Food Processing and Distribution

- Leather

- Fuel and Alternative Fuels

- Medical Devices and Supplies

- Rubber, Resin and other Natural Polymers

- Glass, Glassware, Glass furnaces and other equipment

- Hospital, Laboratory Instruments and Equipment

- Plastic and Synthetic Polymers

- Chemicals, Dyes, Solvents and Petrochemicals

- Manufacturing

- Pharmaceuticals

What do you want to Enquire about?

About Us

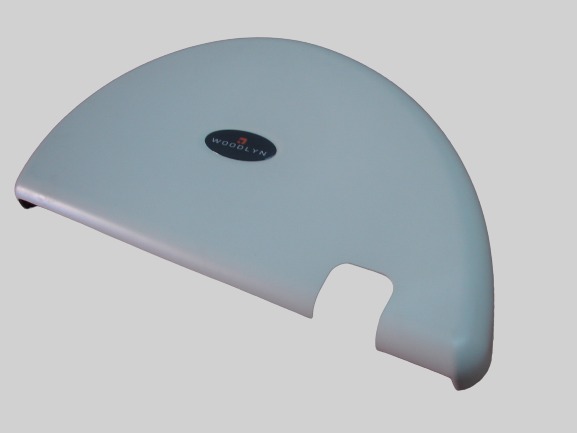

Therm O Pack was started in 1997 by Shivaraman S a technocrat who design build machines and products. On His guidance Therm O Pack started manufacturing and supplying thermoformed products often also called vacuumformed products such as Medical equipment Body panels, Busbody Interior components, Vehicle outer body out of Plastic Materials such as ABS, HIPS, PP, HDPE and Acrylic.

THERM O PACK currently work at Chennai by process vacuumforming and thermoforming , India and marching to its continued success

Manufacturers of Plastic Components, Packing Trays , Handling Trays using Thermoforming and Vaccum forming Technology are widely used in Automotive sectors and Medical equipment sectors.

View more

Our Leadership Team

Mrs. Priya Shivaraman

Business Head

Products & Services

THERMOFORMED PRODUCTS

Product Detail

THERMOFORMED PRODUCTS

Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape. In Thermoformed products the thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. The sheet is then held horizontally over a mold and pressed into or stretched over the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet conforms to the shape of the mold and is held in place until it cools. The excess material is then trimmed away and the formed part is released. Excess material can be reground, mixed with unused plastic, and reformed into thermoplastic sheets.

Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape. In Thermoformed products the thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. The sheet is then held horizontally over a mold and pressed into or stretched over the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet conforms to the shape of the mold and is held in place until it cools. The excess material is then trimmed away and the formed part is released. Excess material can be reground, mixed with unused plastic, and reformed into thermoplastic sheets.

+ Show more

- Show less

VACCUM FORMED PRODUCTS

Product Detail

VACCUM FORMED PRODUCTS

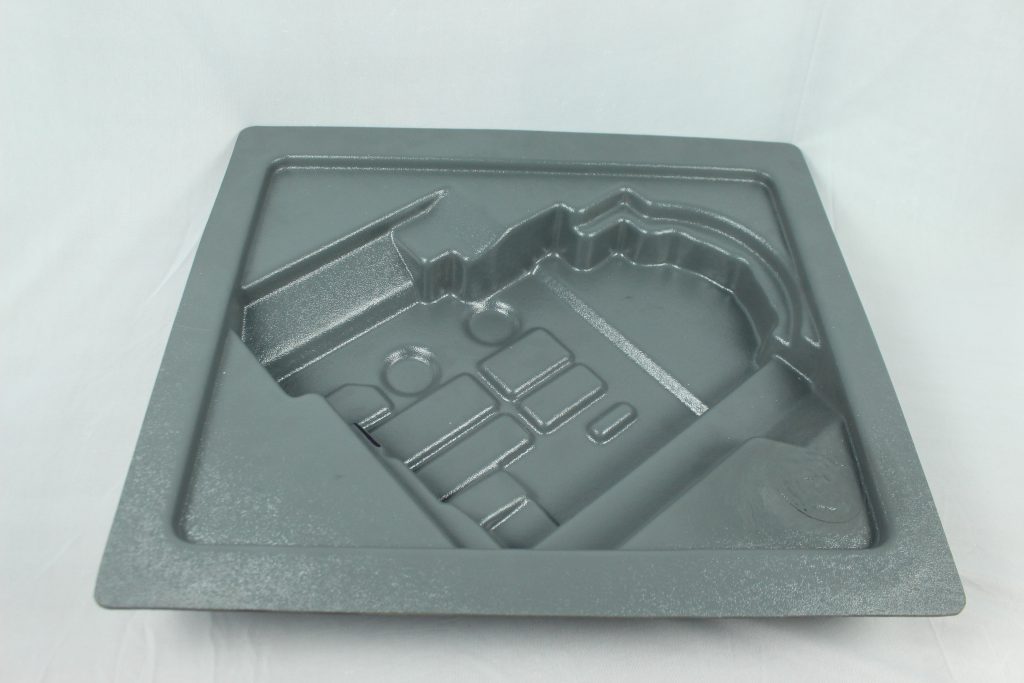

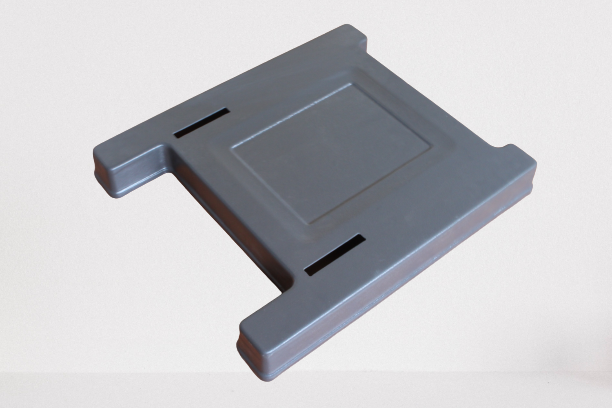

Therm O Pack can design and supply thermoformed and vacuumformed trays for safe transport of your components inside or outside your factory. These trays offer you an ideal solution to safely move products and components from location to location in your facility on your end and to customer safely and damage free. We Do Vacuumforming of various plastic sheets such as ABS, HDPE, PP and HIPS for Handling tray applications, Engineering component packing, stacking and to cover machines. We also custom vacuumform these materials depends of application and requirement of customer.

Therm O Pack can design and supply thermoformed and vacuumformed trays for safe transport of your components inside or outside your factory. These trays offer you an ideal solution to safely move products and components from location to location in your facility on your end and to customer safely and damage free. We Do Vacuumforming of various plastic sheets such as ABS, HDPE, PP and HIPS for Handling tray applications, Engineering component packing, stacking and to cover machines. We also custom vacuumform these materials depends of application and requirement of customer.

We have Inhouse facility to make Protos,moulds and a highly qualified design team to find right solution to clients vacuum forming requirements. Usualy the development of a new products are done in a week to 10 days time depends on profile and size of product required.

Therm O Pack entire arsenal single station thermoformers utilizes the latest technology in software and controllers. This ensures a quality vacuum, pressure or twin-sheet molded part is produced on a consistent basis each and every time. Thermopack’s equipment is maintained and updated to incorporate the latest upgrades, heating science and mechanical requirements. This assures Thermopack commitment to being the leader in forming of new and improved materials to meet every application.

+ Show more

- Show less

MEDICAL PACKING PRODUCTS

Product Detail

MEDICAL PACKING PRODUCTS

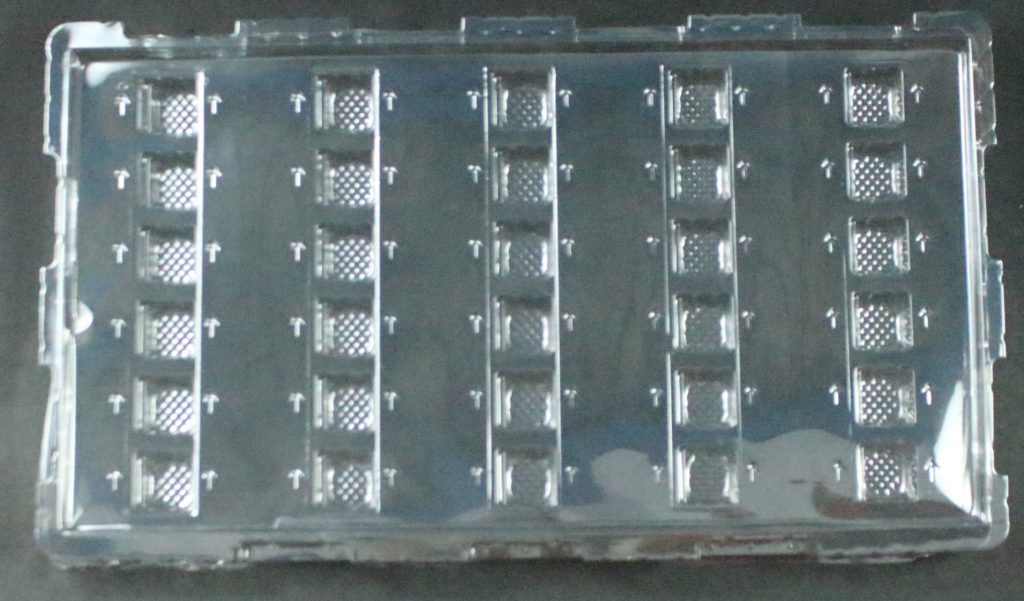

Medical Equipment manufacturers look upon Thermopack to provide them with rigid plastic parts and solutions that are cost effective and their usage is felt on multiple fronts. Therefore we at Thermopack design, develope and supply medical packaging products such as medical equipment covers Vial blisters,Blood collection tray,Retart packaging etc. Our scope includes the following Innovative Plastic Designs to solve new industry challenges: Thermopack has an able design team who put its efforts and skills to design to the maximum accuracy to meet customers satisfaction which is the key for them. Thermopack is the destination for a customer seeking solution for all his needs regarding Medical Equipment covers and medical packaging trays depends on their needs.

Medical Equipment manufacturers look upon Thermopack to provide them with rigid plastic parts and solutions that are cost effective and their usage is felt on multiple fronts. Therefore we at Thermopack design, develope and supply medical packaging products such as medical equipment covers Vial blisters,Blood collection tray,Retart packaging etc. Our scope includes the following Innovative Plastic Designs to solve new industry challenges: Thermopack has an able design team who put its efforts and skills to design to the maximum accuracy to meet customers satisfaction which is the key for them. Thermopack is the destination for a customer seeking solution for all his needs regarding Medical Equipment covers and medical packaging trays depends on their needs.

+ Show more

- Show less

BLISTER PACKAGING PRODUCTS

Product Detail

BLISTER PACKAGING PRODUCTS

We at Thermopack do complete solutions for packaging of Various products using Blister packing tray, Clamp shell tray, PET blisters, PVC blister, PET Blister, PET antistatic tray depends upon customers requirement and size. We are proud to be one of the Leading supplier of Large sized blisters up to 1200mm X 800mm in size.

We at Thermopack do complete solutions for packaging of Various products using Blister packing tray, Clamp shell tray, PET blisters, PVC blister, PET Blister, PET antistatic tray depends upon customers requirement and size. We are proud to be one of the Leading supplier of Large sized blisters up to 1200mm X 800mm in size.

+ Show more

- Show less

FOOD PACKAGING PRODUCTS

Product Detail

FOOD PACKAGING PRODUCTS

At Thermopack we do disposable food packaging trays for Fast foods, burger trays, sandwich trays , biscuit trays of various sizes, cake tray, confectionary trays, and other food packaging such as fruits and vegetables. We have fully automated German line to produce these trays in high volume also at clean environment.

At Thermopack we do disposable food packaging trays for Fast foods, burger trays, sandwich trays , biscuit trays of various sizes, cake tray, confectionary trays, and other food packaging such as fruits and vegetables. We have fully automated German line to produce these trays in high volume also at clean environment.

- Biscuit manufacturers

- Confectionary manufacturers

- Sweets and savories manufacturers

- Bakery product manufacturers

- Fast food suppliers

- Fruits and vegetable farms

+ Show more

- Show less

RETURNABLE PACKING PRODUCTS

Product Detail

RETURNABLE PACKING PRODUCTS

Thermopack is leader in design, develop and supply returnable packaging trays and solutions. We cater returnable packaging from heavy metal component such as Shafts, pulleys, gears, clutches , engines, camshafts etc. We do packing solutions for plastic products such as dashboards, trims, bumpers, instrument clusters , large panels . Our returnable packaging trays/separators are familiar with most of the major Automotive such as Daimler India, Ford India, Renault Nissan Automotive and Ashok Leyland.

Thermopack is leader in design, develop and supply returnable packaging trays and solutions. We cater returnable packaging from heavy metal component such as Shafts, pulleys, gears, clutches , engines, camshafts etc. We do packing solutions for plastic products such as dashboards, trims, bumpers, instrument clusters , large panels . Our returnable packaging trays/separators are familiar with most of the major Automotive such as Daimler India, Ford India, Renault Nissan Automotive and Ashok Leyland.

- Automotive components manufacturer

- Casting, Forging and machined components

- Plastic molded component manufacturers

- Dashboard, Door trim and other trim manufacturers

- Light manufacturers

- Accessories manufacturers

+ Show more

- Show less

CONSUMER PACKING PRODUCTS

Product Detail

CONSUMER PACKING PRODUCTS

Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape. The thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. The sheet is then held horizontally over a mold and pressed into or stretched over the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet conforms to the shape of the mold and is held in place until it cools.

Thermoforming describes the process of heating a thermoplastic sheet to its softening point, stretching it over or into a single-sided mold, and holding it in place while it cools and solidifies into the desired shape. The thermoplastic sheet is clamped into a holding device and heated by an oven using either convection or radiant heat until it is softened. The sheet is then held horizontally over a mold and pressed into or stretched over the mold using vacuum pressure, air pressure, or mechanical force. The softened sheet conforms to the shape of the mold and is held in place until it cools.

The excess material is then trimmed away and the formed part is released. Excess material can be reground, mixed with unused plastic, and reformed into thermoplastic sheets.

+ Show more

- Show less

View more

Brochures

Gallery(5)