- Seeds, Fertiliser, Pesticides and Agro-input chemicals

- Textile

- Maritime

- Food Processing and Distribution

- Leather

- Fuel and Alternative Fuels

- Commercial Vehicles and Fleet Management

- Rubber, Resin and other Natural Polymers

- Glass, Glassware, Glass furnaces and other equipment

- Aerospace, Satellite Components and Services

- Manufacturing Components and Supplies

- Plastic and Synthetic Polymers

- Chemicals, Dyes, Solvents and Petrochemicals

- Automobile and Automobile Accessories

- Mechanical Components and Spare Parts

- Manufacturing

- Metalworking and Fabrication

- Pharmaceuticals

What do you want to Enquire about?

About Us

View more

Our Leadership Team

Mr. Sanjeev Ahuja

Business Head

Mr. Vaibhav Ahuja

Business Head

Products & Services

Tapered Roller Bearing

Product Detail

Tapered Roller Bearing

Angular contact tapered roller bearings are designed to accommodate combined simultaneously acting radial and axial loads. The bearing ability to accommodate the axial load is largely determined by the taper angle of the outer ring raceway, called the contact angle. When increasing the contact angle, the axial load capacity of the bearing increases with the corresponding decrease of the radial load capacity and permitted rotation speed. Even slight shaft misalignment relative to the housing is unacceptable when using angular contact tapered roller bearings.

Angular contact tapered roller bearings are produced single row accommodating only axial load in one direction, as well as double row and four-row accommodating axial load in both directions. It is possible to supply single row bearings matched in pairs and completed with intermediate rings to secure the necessary clearance. In the general engineering fields, the most common are single row bearings, double row, and four-row bearings are usually used in heavy machinery. Angular contact tapered roller bearings have a split design, which makes their mounting easier.

Angular contact tapered roller bearings are produced with pressed steel cages. Large-size bearings are equipped with massive cages made of steel or brass and for special application cages made of glass fiber reinforced polyamide can be produced.

+ Show more

- Show less

Thrust Bearing

Product Detail

Thrust Bearing

Taper Roller Thrust Bearing

CAN Taper Roller Thrust bearings include rollers that have conical sections. These bearings are designed primarily to support axial loads at contact angles between 30˚ and 90˚. These bearing are suited for applications where extremely high thrust loads like in crane hooks, coal pulverizer, etc. These bearings can be supplied with a full complement of rollers.

Thrust Ball Bearing

The Thrust Ball bearings are used for high axial loads at low speeds. These cannot operate at high speed when centrifugal or radial force cannot be handled by the bearings. They can be located endwise in one direction only.

+ Show more

- Show less

Cylindrical Roller Bearing

Product Detail

Cylindrical Roller Bearing

Cylindrical Roller Bearing

Radial cylindrical roller bearings are intended to accommodate the radial loads. They have much greater radial load capacity compared to the deep groove ball bearings of equal dimensions, but they are inferior to them as per high-speed characteristics. Cylindrical roller bearings are very sensitive to the misalignment of inner rings relative to outer rings when tension concentration at the edges of rollers appears. To reduce this tension the modern roller bearings contact geometry between roller and raceway has a special «logarithmic» profile

Single row radial cylindrical roller bearings are produced in many structural modifications, the most common of which are: without flanges and with one flange on the inner ring, with one flange on the inner ring and flat thrust ring, without flanges and with one flange on the outer ring. If it is necessary to reduce the unit radial dimensions, single row roller bearings can be supplied without inner or outer rings, in this case, the second raceway is formed directly on the shaft or in the housing of the unit. Double row and multi-row radial cylindrical roller bearings are produced for various special applications.

+ Show more

- Show less

Needle Roller Bearing

Product Detail

Needle Roller Bearing

Small cylindrical rollers with the length are several times more than their diameter is called needle rollers.

Radial needle roller bearings are designed to accommodate only radial loads. With the equal load capacity, they have much smaller radial dimensions compared to the dimensions of other types of bearings having with them the identical hole diameters. This property makes them very popular to use in the machines with limited radial space. A negative characteristic of the bearings is their extremely small capacity to accommodate the angular shaft misalignments relative to the housing.

The radial needle roller bearings have enormous kinds of designs. The most common are bearings with the pressed outer rings, with the rings made of bearing steel, as well as the cages with the rollers without rings. Usually, the bearings have one or two rows of rolling elements. The bearings can be open or have protective contact seals.

Radial needle roller bearings are produced with pressed steel or glass fiber reinforced polyamide cages. To provide a very high radial load capacity the bearings can be manufactured without the cage with the maximum number of rollers.

+ Show more

- Show less

Deep Groove Ball Bearing

Product Detail

Deep Groove Ball Bearing

Due to various application possibilities and relatively low prices, deep groove ball bearings are the most common out of all the variety of rolling bearings. They have a simple design and the ability to operate at high speed and moderate load. When operating, they do not practically need maintenance. These bearings are able to accommodate both the radial loads and the axial loads in both directions.

Compared with other types of rolling bearings, deep groove ball bearings operate with minimal friction losses. The alignment of seats for these bearings shall be kept within such limits that the misalignment of the outer rings relative to the inner rings was slight, even with the increased bearing clearance. The bearings shall be mounted on hard double-seat shafts which deflection under the influence of the external forces does not cause excessive misalignment of the shaft axis relative to the mounting bore axis.

Deep groove ball bearings with protective metal shields or contact and contactless seals are widely distributed. They are used in the cases when due to the limited size or maintenance inconveniences, mounting of special sealing devices to protect the bearing from dirt or to keep the lubrication in is undesirable.

+ Show more

- Show less

Integral Shaft Bearing

Product Detail

Integral Shaft Bearing

Due to their design, integral shaft bearings are very compact, allowing for either two rows of balls or a row of balls and a row of rollers. Our bearings are pre-packed with lubricant to ensure a long lifespan and are sealed to resist contamination.

If you need some more flexibility when it comes to integral shaft bearings, outer race and shaft diameter variations are available, as are shaft extension modifications. It’s this flexibility that allows integral shaft bearings to be used in a number of applications, including those in the automotive, agricultural, and landscaping industries.

+ Show more

- Show less

Spherical Roller Bearing

Product Detail

Spherical Roller Bearing

As a rule radial spherical roller bearings have two rows of rollers with a common sphered raceway in the outer ring. They have higher radial load capacity compared to other types of bearings with equal dimensions and they are able to compensate significant misalignment and shaft deflections (up to 3°). They can also accommodate the combined radial and axial load. However, it is not recommended to operate them under heavy axial loads, because only one row of rollers will work in this case. Radial spherical roller bearings are used in the supports of pumps, powerful fans, smoke exhausts, saw frames, gears, propeller shafts, rolling mills and in the supports of other machines and mechanisms, which operate under heavy radial loads and inevitable misalignment of seats.

Bearings can be produced with both cylindrical and tapered bores in the inner rings. The latter is mounted on the tapered shaft neck or on an adapter or withdrawal sleeve. Radial spherical roller bearings are usually mounted on the long shafts subjected to significant deflection, or in the supports of detached housings. The bearings with adapter sleeves are mounted on smooth multi-supporting shafts. As a rule, bearing with the tapered bore as well as bearings with withdrawal sleeves are mounted on the terminal supports of shaft or axis. The presence of tapered bore in the bearings considerably facilitates their mounting and dismounting

+ Show more

- Show less

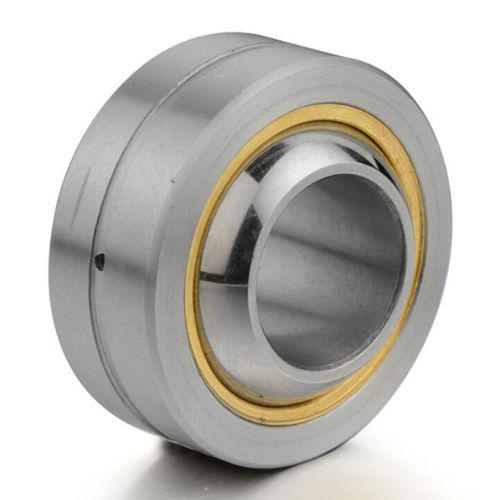

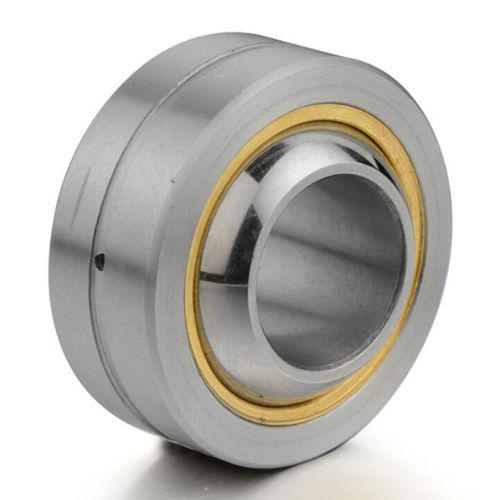

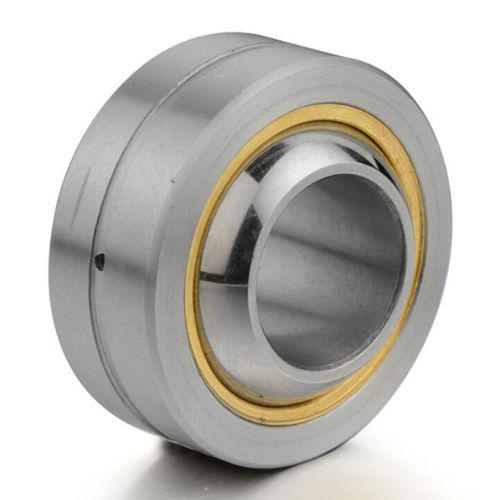

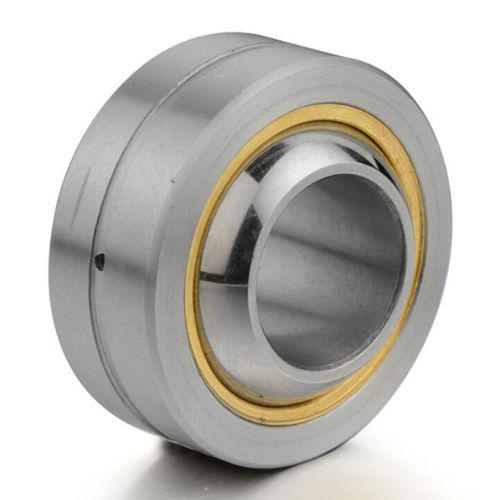

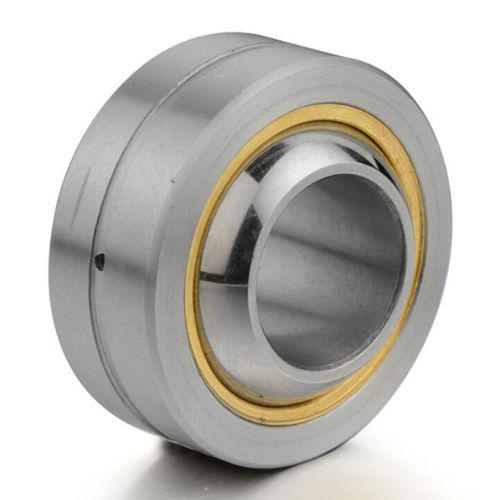

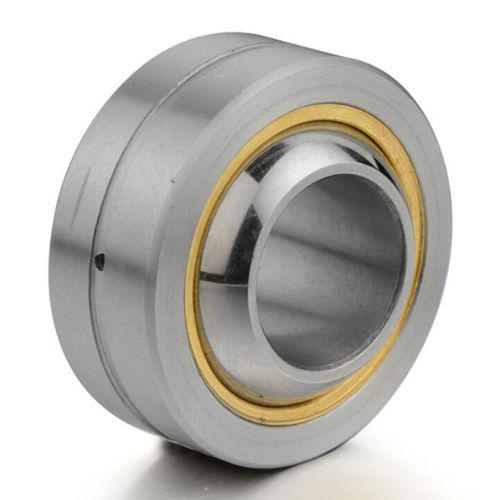

Spherical Plain Bearing

Product Detail

Spherical Plain Bearing

Spherical plain bearings are plain bearings, inner and outer rings of which have sphered sliding surfaces. Spherical plain bearings are designed for the transmission of radial, axial and combined loads, including shock loads in the joints of machine parts and mechanisms where it is necessary to provide with spatial complex or vibrating, rocking, rotating and simple movements at low speeds. Radial, angular contact, and thrust spherical bearings are produced depending on the nature of transmitted loads.

All spherical plain bearings can be divided into two groups according to the method of the working surface lubrication. There are bearings requiring the lubrication and self-lubricating bearings the sliding surfaces of which are made of special materials. The latter are used in the units with higher durability requirements, or when there are difficulties in supports maintenance when it is unreasonable to use lubrication requiring bearings.

+ Show more

- Show less

View more