Benefits of Using TATA Fe 550D TMT Bars

Author: Tata nexarc | Published on: 15th July 2024 | 4 min read

Table of contents:

| Section | Description |

| Overview | Introduction to TMT bars and their importance |

| Properties | Key properties enhancing performance and durability |

| Benefits | Advantages like strength, cost-effectiveness, and versatility |

| Quality Assurance | Ensuring high quality through standards and testing |

| Comparison | Differences and specific advantages of Fe 550D over other grades |

| Conclusion | Summary of benefits and final thoughts on TATA Fe 550D TMT bars |

Choosing the right grade is essential for the safety and longevity of any structure. TATA Fe 550D TMT bars stand out for their superior properties and benefits, making them a preferred choice for many builders and engineers.

TMT bars undergo a thermo-mechanical treatment process. This treatment gives them high strength and ductility. They are used in various construction projects, from residential buildings to large infrastructure projects.

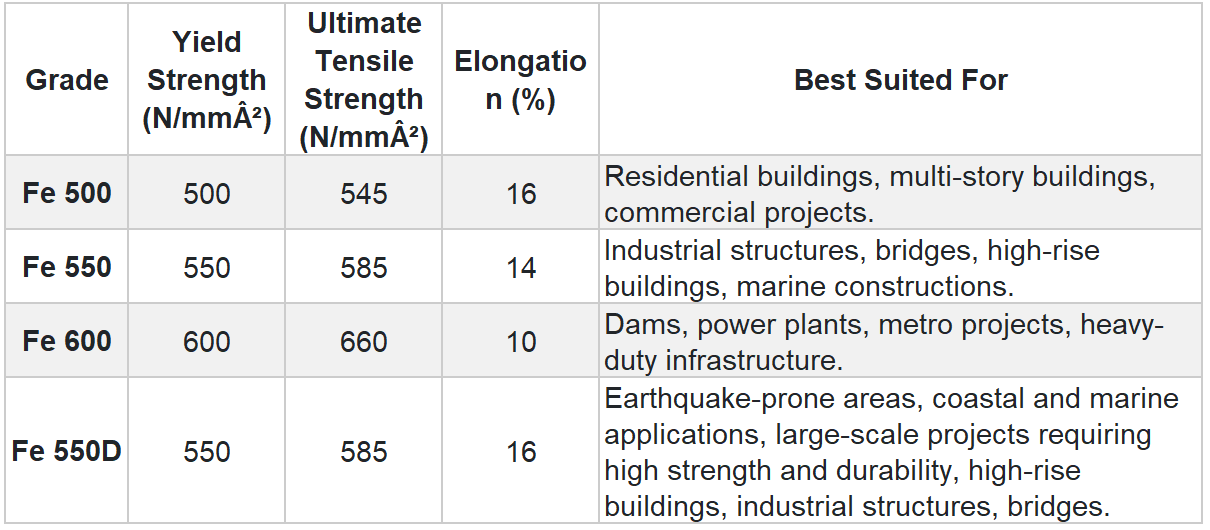

Importance of Choosing the Right Grade: Selecting the right grade of TMT bars ensures the stability and safety of structures. Grades like Fe 500, Fe 550, and Fe 600 offer different strengths and features. Among these, TATA Fe 550D TMT bars offer a balanced combination of strength and flexibility.

Introduction to TATA Fe 550D TMT Bars: TATA Fe 550D TMT bars are known for their high yield strength and ductility. They are designed to withstand extreme conditions, including earthquakes and fires. These bars are also corrosion-resistant, making them ideal for various construction projects.

High demand states: Maharashtra, Karnataka, Tamil Nadu, Andhra Pradesh, Telangana

High demand diameters: 8 mm, 10 mm, 12 mm, 16 mm, 18 mm, 20 mm, 25 mm, 32 mm

Properties of TATA Fe 550D TMT Bars

Chemical Composition

- Precise Mix: Includes carbon (0.25%), manganese, sulphur (0.04%), and phosphorus (0.04%).

- Combined S+P Content: Around 0.07%.

- Benefits: High strength and durability with enhanced weldability and reduced brittleness.

Mechanical Properties (Strength, Ductility)

- Yield Strength: 550 N/mm².

- Ultimate Tensile Strength: 585 N/mm².

- Elongation: 16%, ensuring flexibility during construction and the ability to absorb significant stress without fracturing.

Corrosion Resistance

- Enhanced Resistance: Lower levels of sulphur and phosphorus reduce rust and corrosion.

- Ideal for: Coastal areas and high-humidity environments.

- Benefit: Extends the life of structures and reduces maintenance costs.

Earthquake Resistance

- Seismic Absorption: Designed to absorb and dissipate seismic energy.

- High Ductility: Can withstand dynamic loading and deformation during seismic events.

- Benefit: Provides additional safety for structures in earthquake-prone areas.

Fire Resistance

- High Temperature Tolerance: Maintains structural integrity at temperatures ranging from 400 to 600 °C.

- Benefit: Enhances protection against fire hazards, ensuring building safety.

Benefits of Using TATA Fe 550D TMT Bars

Enhanced Durability

- High Strength: TATA Fe 550D TMT bars boast a yield strength of 565 N/mm² and an ultimate tensile strength of 610 N/mm², ensuring that structures built with these bars can withstand significant loads and stresses over time. This high strength makes them particularly suitable for long-lasting structures, providing stability and integrity for decades.

- Improved Durability: The low carbon, sulphur, and phosphorus content in TATA Fe 550D TMT bars enhances their resistance to environmental factors such as corrosion and temperature variations. This results in extended lifespan and reduced maintenance costs for buildings and infrastructure.

Cost-Effectiveness

- Long-Term Savings: Although the initial cost of TATA Fe 550D TMT bars may be higher than lower-grade alternatives, their superior durability and low maintenance requirements lead to significant cost savings over time. Fewer replacements and repairs translate into lower overall expenses for building owners.

- Reduced Quantity Needed: Due to their high strength, fewer bars are required to achieve the same structural support, which reduces the overall material and labour costs. This makes TATA Fe 550D TMT bars a cost-effective choice for large-scale construction projects.

High Yield Strength

- Support for Heavy Loads: With a high yield strength of 565 N/mm², TATA Fe 550D TMT bars can support heavy loads without deforming. This property is essential for high-rise buildings, bridges, and other large infrastructure projects that require robust structural support.

- Structural Integrity: The high yield strength ensures that buildings and structures maintain their shape and integrity under significant stress, contributing to overall safety and reliability.

Better Bonding with Concrete

- Ribbed Surface: TATA Fe 550D TMT bars have a ribbed surface that ensures better bonding with concrete. This ribbed texture increases the surface area for concrete adherence, enhancing the composite strength of the concrete-steel structure.

- Improved Structural Strength: The superior bonding between TATA Fe 550D TMT bars and concrete improves the overall structural integrity and strength of the building, making it more resistant to external forces and loads.

Versatility in Various Applications

- Wide Range of Uses: TATA Fe 550D TMT bars are suitable for a variety of applications, including residential, commercial, and industrial structures. Their properties make them adaptable to different construction needs, from small homes to large infrastructure projects.

- Critical Infrastructure: These bars are ideal for critical infrastructure such as bridges, dams, and towers, where high strength and durability are paramount. Their resistance to seismic activity and environmental factors makes them a preferred choice for such demanding applications.

Quality Assurance for TATA Fe 550D TMT Bars

BIS Certification: TATA Fe 550D TMT bars are certified by the Bureau of Indian Standards (BIS) under IS 1786. This certification ensures that the bars meet stringent quality and performance standards, guaranteeing their reliability. The BIS certification involves rigorous testing protocols that assess the bars' mechanical and chemical properties, ensuring they meet the specified requirements for yield strength, tensile strength, and elongation. The yield strength for Fe 550D is 565 N/mm², and the ultimate tensile strength is 610 N/mm², with an elongation of 16%.

Compliance with International Standards: TATA Fe 550D TMT bars are manufactured to comply with various international standards, making them suitable for global construction projects. These bars meet or exceed the requirements set by international standards, such as ASTM, DIN, and JIS, ensuring their acceptance in diverse markets. This compliance guarantees that the bars perform reliably under different environmental conditions and construction demands.

Rigorous Testing and Quality Control

The production of TATA Fe 550D TMT bars involve a comprehensive quality control process that includes multiple stages of testing and inspection. The manufacturing process begins with the careful selection of raw materials, which are then subjected to a series of metallurgical treatments, including quenching and self-tempering, to enhance their strength and durability. The final products undergo stringent tests for chemical composition, mechanical properties, and dimensional accuracy.

- Chemical Testing: Ensures the bars have the correct composition of carbon, sulphur, phosphorus, and other alloying elements. For Fe 550D, the maximum allowable carbon content is 0.25%, sulphur is 0.035%, and phosphorus is 0.035%.

- Mechanical Testing: Includes tests for yield strength, tensile strength, and elongation to ensure the bars meet the specified standards. Fe 550D bars are tested to have a minimum yield strength of 565 N/mm² and an ultimate tensile strength of 610 N/mm².

- Dimensional Testing: Ensures that the bars have the correct size and shape, which is crucial for their proper application in construction projects.

Comparison with Other TMT Bar Grades

Specific Advantages of Fe 550D over Other Grades

TATA Fe 550D TMT bars offer a unique balance of strength and ductility, making them exceptionally versatile for a wide range of applications.

- Enhanced Ductility: Fe 550D TMT bars provide higher elongation compared to regular Fe 550 bars, with an elongation percentage of around 16%. This high ductility ensures better performance under seismic conditions and allows the bars to absorb and dissipate energy during an earthquake, reducing the risk of structural failure.

- Corrosion Resistance: Fe 550D TMT bars are engineered with lower carbon, sulphur, and phosphorus content, enhancing their resistance to corrosion. This makes them particularly suitable for coastal and marine applications, where exposure to moisture and salt can lead to rusting and deterioration of steel.

- Cost-Effectiveness: While Fe 550D bars might have a slightly higher upfront cost compared to Fe 500, their superior strength and durability can lead to long-term savings by reducing the need for frequent repairs and maintenance. This makes them a cost-effective choice for large-scale projects.

- Weldability: The lower carbon content in Fe 550D TMT bars improves their weldability, ensuring strong and seamless joints during construction. This property is crucial for complex structures that require extensive welding.

How Tata nexarc Can Help with Purchasing TATA Fe 550D TMT Bars Online

1. Wide Availability: Tata nexarc ensures TATA Fe 550D TMT bars are accessible through a broad network of authorized dealers and distributors.

2. Easy Online Ordering: The platform offers a user-friendly interface for browsing, comparing, and purchasing TATA Fe 550D TMT bars, ensuring a seamless buying experience.

3. Competitive Pricing: Tata nexarc provides competitive and transparent pricing, helping buyers get the best deals and stay informed about market trends.

4. Quality Assurance: All products on Tata nexarc are verified for quality, ensuring buyers receive high-grade TATA Fe 550D TMT bars.

5. Comprehensive Customer Support: Tata nexarc offers excellent customer support to assist with queries and ensure a smooth purchasing process, enhancing overall customer satisfaction.

Conclusion

TATA Fe 550D TMT bars offer numerous benefits, including high strength, durability, corrosion resistance, and cost-effectiveness. Their exceptional yield strength of 565 N/mm² and tensile strength of 610 N/mm² ensure they can support heavy loads and withstand harsh conditions. Additionally, their enhanced ductility and elongation of 16% make them ideal for seismic zones, providing additional safety. These bars are also designed to resist corrosion, making them suitable for coastal and humid environments. Whether for residential buildings, commercial projects, industrial structures, or large infrastructure developments like bridges and dams, TATA Fe 550D TMT bars are a reliable and efficient choice. Their availability through platforms like Tata nexarc ensures easy access and competitive pricing, making them a preferred option for builders and engineers.

No Spam Calls,Only Relevant Information.

-

Competitive prices

-

Easy credit options

-

Quality products assured

-

Verified sellers